Trailer Lift Jack: Reliable Vertical Support for Every Hauling Task

Every trailer operator knows — a reliable lift jack is more than a convenience; it’s a safety essential.

A trailer lift jack provides vertical support that keeps trailers stable during loading, coupling, and maintenance, preventing frame damage and ensuring operator safety.

Zhongteli, a professional manufacturer of forged trailer components, designs lift jacks that combine structural strength, smooth motion, and corrosion resistance to handle demanding working conditions.

Why Reliable Lifting Matters

Lifting systems are subject to constant stress. Inconsistent or weak jacks can cause misalignment, jack failure, or even load tipping.

Typical Problems with Low-Quality Jacks:

-

Thread binding due to poor machining

-

Tube bending under uneven load

-

Rust and corrosion reducing load capacity

-

Inaccurate height adjustment

-

Base plate instability on rough ground

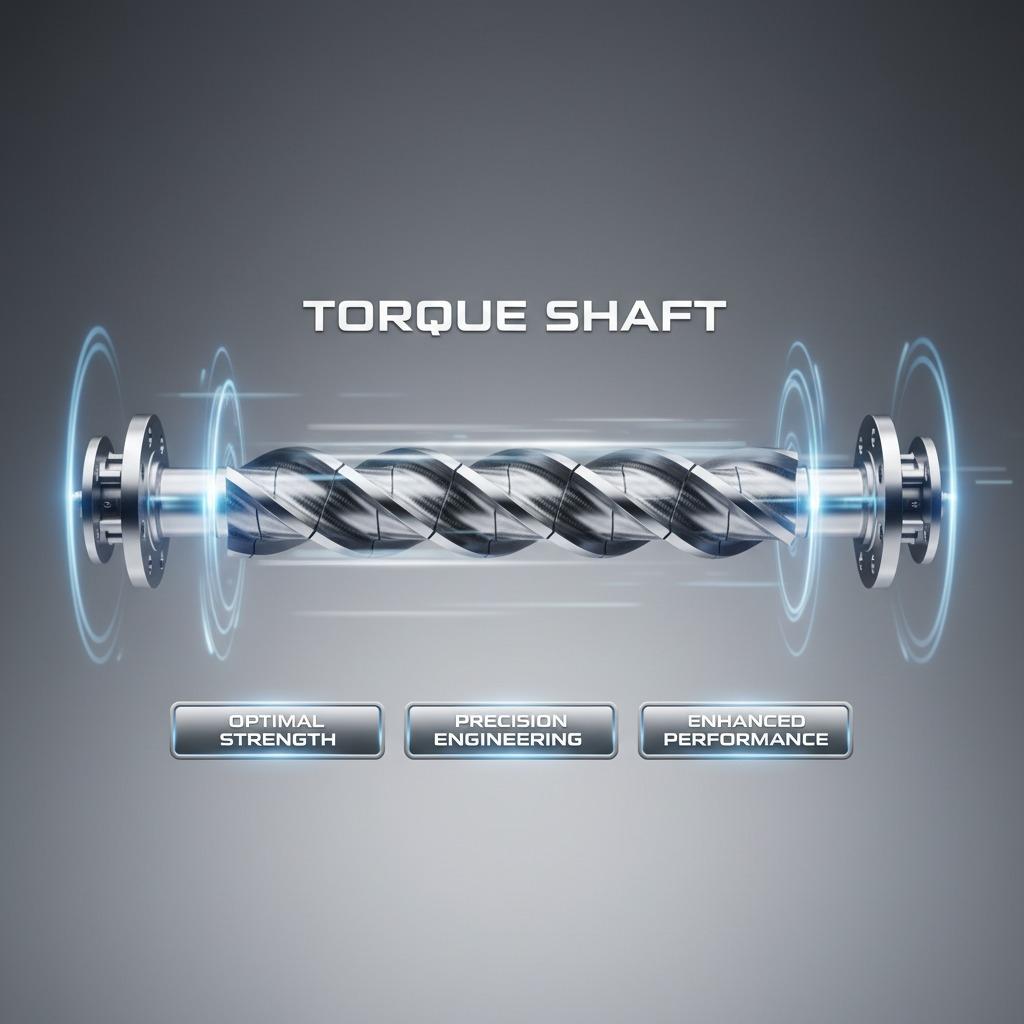

According to SAE International standards, consistent torque performance and thread precision are critical to ensuring stability and preventing load drift during vertical lifting.

Comparing Trailer Lift Jacks by Type

| Type | Load Range | Main Advantage | Typical Use |

|---|---|---|---|

| Manual Lift Jack | 2,000–5,000 lbs | Simple, durable, no maintenance | Utility or light cargo trailers |

| Drop Leg Jack | 5,000–8,000 lbs | Adjustable height, quick setup | Farm and construction trailers |

| Dual Gear Lift Jack | 8,000–12,000 lbs | Smooth torque control | Industrial heavy-duty transport |

| Electric Lift Jack | Variable | Automation, easy operation | RVs, OEM integrated systems |

While electric jacks are growing in popularity, mechanical trailer lift jacks remain the top choice for professionals who prioritize strength, reliability, and easy maintenance.

Inside Zhongteli’s Forged Lift Jack Design

Each Zhongteli lift jack is engineered for durability and precision, combining forged construction, precision machining, and protective coatings for long-term performance.

Product Advantages:

-

All-Forged Steel Housing – Prevents structural deformation under heavy load.

-

Smooth Gear Mechanism – Ensures consistent torque and minimal wear.

-

Protective Zinc or Epoxy Coating – Rust-proof and weather-resistant.

-

Precision Threaded Shaft – Provides smooth and steady lift.

-

Customizable Handles and Bases – OEM options available for all markets.

All Zhongteli lift jacks comply with ISO 9001, EN 12195-3, and CE certification standards, ensuring mechanical integrity and global export readiness.

Applications Across Industries

Zhongteli’s trailer lift jacks are designed for versatility across multiple sectors:

-

Construction Hauling Equipment – Supports heavy-duty transporters and site trailers.

-

Cargo & Logistics Fleets – Ensures stability during frequent loading cycles.

-

Agricultural Implements – Durable performance in muddy or rough environments.

-

Utility and Industrial Trailers – Smooth lift and reliable coupling on uneven surfaces.

-

OEM Export Market – Custom jacks tailored to specific trailer configurations.

The National Highway Traffic Safety Administration (NHTSA) emphasizes that stable lifting systems significantly reduce the risk of trailer tip-overs during coupling or maintenance.

Selecting the Right Trailer Lift Jack

| Application | Model | Load Capacity | Coating | Key Benefit |

|---|---|---|---|---|

| Light Cargo Trailer | Manual Top-Wind | 2,000–3,000 lbs | Zinc | Compact, smooth operation |

| Farm Trailer | Drop Leg | 5,000–7,000 lbs | Epoxy | Adjustable and rugged |

| Industrial Trailer | Dual Gear | 8,000–12,000 lbs | Powder | High torque efficiency |

| OEM Production | Custom Build | Variable | HDG | Configurable for market demand |

Zhongteli engineers offer design consultation to help customers choose the optimal combination of load range, crank configuration, and coating for specific applications.

Frequently Asked Questions

Q1: What defines a “lift jack” compared to standard jacks?

A lift jack provides precise vertical elevation and stabilization, often with higher torque and capacity.

Q2: Are Zhongteli’s lift jacks suitable for outdoor or marine environments?

Yes, all models are treated with anti-corrosion coatings suitable for long-term outdoor exposure.

Q3: What’s the typical service life of a Zhongteli trailer lift jack?

Generally 8–12 years, depending on frequency of use and maintenance.

Q4: Does Zhongteli provide OEM manufacturing?

Yes — custom labels, crank handles, and mounting options are available for global OEM partners.

Lifting Power You Can Rely On

From everyday cargo trailers to large-scale equipment haulers, Zhongteli’s trailer lift jacks are built to last.

They deliver precision lifting, superior corrosion resistance, and long-term reliability — wherever stability matters most.

Explore more lifting solutions on Zhongteli’s homepage or contact us here to discuss OEM options or bulk procurement.