Trailer Landing Gear Manufacturer: Stability Engineered for Every Load

When a 20-ton trailer disconnects from its tractor, all that weight rests on one system — the landing gear.

A failure here can cause a collapse, damaged cargo, and even injury. That’s why trailer landing gear is more than a simple support device; it’s a structural safeguard, designed to keep fleets stable and operators safe.

Zhongteli, a professional trailer landing gear manufacturer, specializes in forging and machining landing assemblies that deliver strength, smooth operation, and long-lasting protection against corrosion, vibration, and mechanical fatigue.

The Real-World Pain Point: Support That Never Fails

For logistics operators and trailer OEMs, landing gear reliability defines operational safety.

When used daily under dust, rain, and mechanical stress, a substandard system quickly reveals its flaws.

Frequent Industry Problems Include:

-

Weak weld seams causing frame bending

-

Gearbox seizure after exposure to moisture

-

Uneven leg extension leading to tilt or collapse

-

Corrosion reducing load-bearing strength

As SAE International mechanical standards highlight, proper torque distribution and shaft alignment are essential in high-load landing systems. Zhongteli’s products follow these standards to ensure safe static support and balanced lifting under any condition.

Trailer Landing Gear vs. Standard Support Systems

| Feature | Trailer Landing Gear | Standard Support Jack |

|---|---|---|

| Load Capacity | 20,000–80,000 lbs | 2,000–10,000 lbs |

| Operation | Dual-speed gearbox | Single gear or manual screw |

| Durability | Industrial forged steel | Mild steel / cast components |

| Use Environment | Heavy trucks, tankers, cargo trailers | Light utility or small trailers |

| Stability | Dual-leg synchronized | Single-leg / manual adjustment |

Unlike regular jacks, landing gear systems are built for synchronized, high-torque lifting — essential for large freight trailers and tankers where balance determines safety.

Why Zhongteli Leads in Landing Gear Manufacturing

Precision, endurance, and design flexibility set Zhongteli apart.

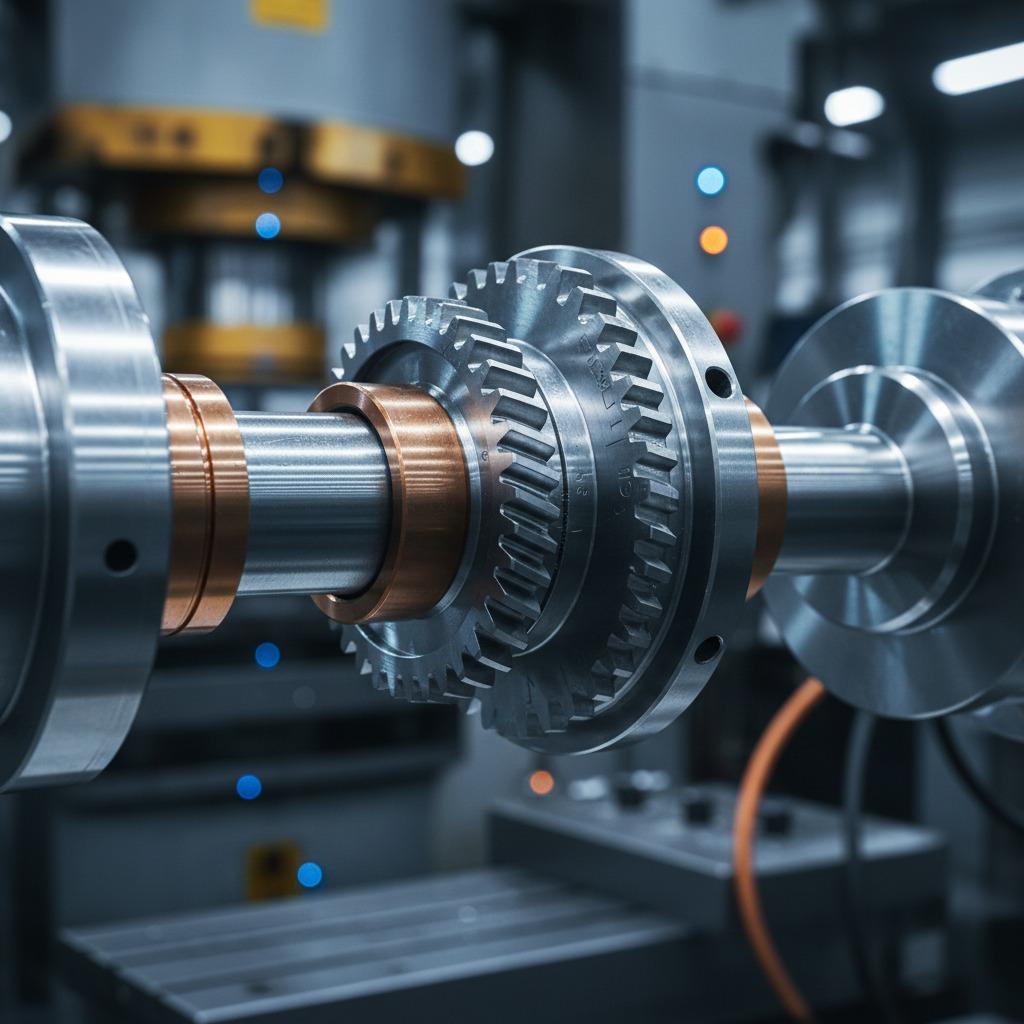

Each unit is produced using forged steel, dual-speed gearboxes, and zinc or epoxy coatings that resist corrosion, even in marine or winter road conditions.

Core Advantages:

-

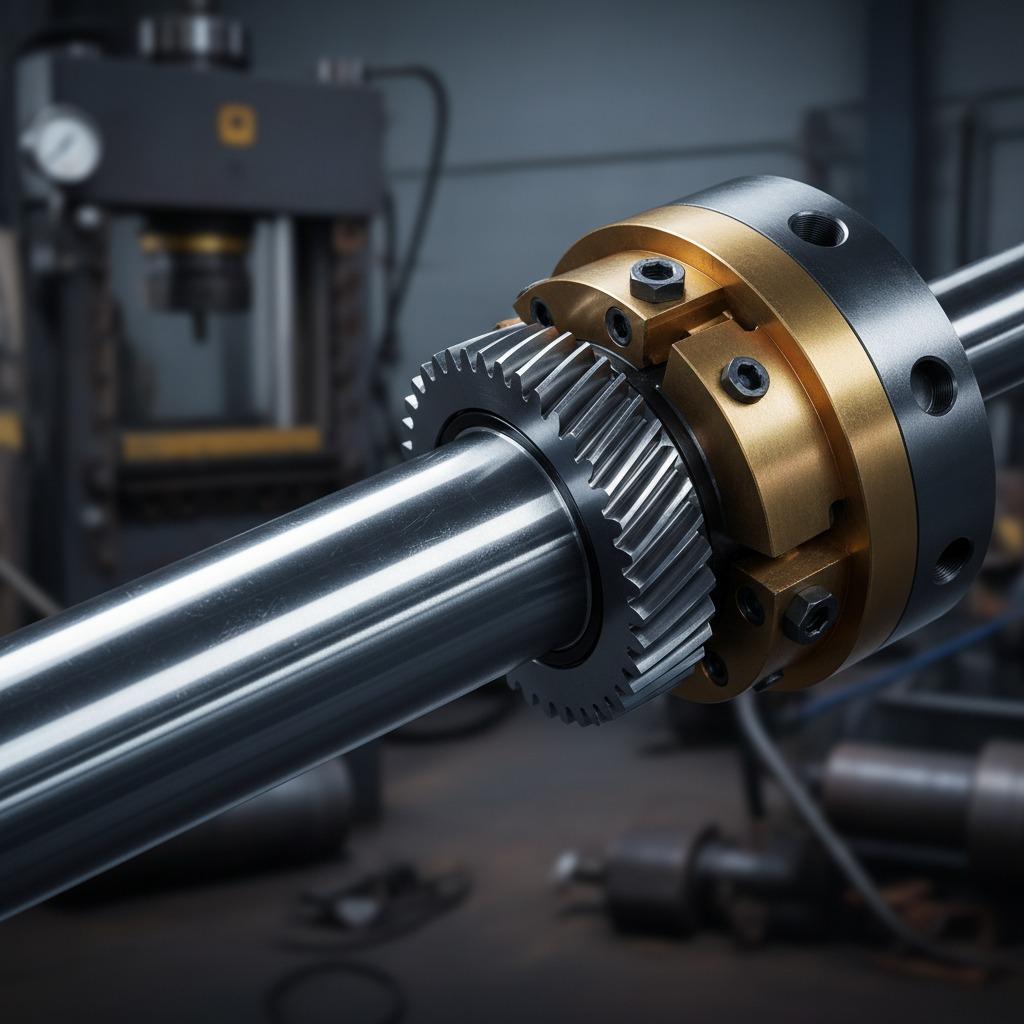

Forged Dual-Leg Design – Symmetrical load distribution under pressure.

-

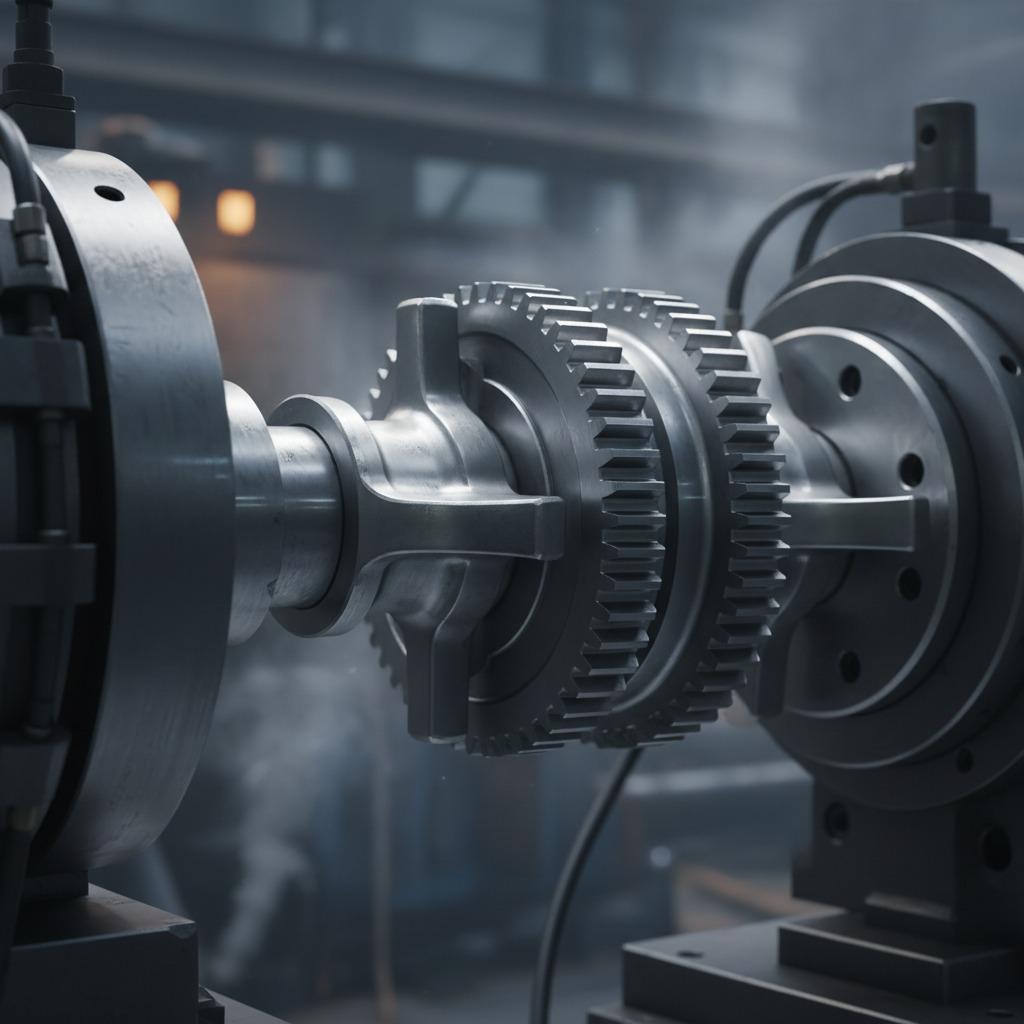

High-Torque Gearbox System – Smooth lifting and secure retraction.

-

Anti-Corrosion Surface – Zinc plating or hot-dip galvanizing for long-term use.

-

OEM Integration Ready – Mounting flexibility for custom trailer designs.

-

Endurance Testing – Over 15,000 lift cycles verified under ISO and EN standards.

Every Zhongteli landing gear assembly meets ISO 9001 and EN 12195-3 compliance, ensuring compatibility with global trailer fleets and OEM installations.

Industrial Applications Across the Globe

Zhongteli’s landing gear systems are engineered for continuous use in demanding fields:

-

Long-Haul Freight & Container Trailers – Withstands repetitive coupling cycles.

-

Tanker & Bulk Carriers – Prevents collapse during uneven loading.

-

Construction & Mining Fleets – Operates in dust, mud, and vibration-prone environments.

-

Agricultural Transport – Stable on unpaved or soft surfaces.

-

OEM Assembly Lines – Custom-tailored for global brand integration.

The National Highway Traffic Safety Administration (NHTSA) notes that landing gear integrity directly affects braking balance and rollover prevention — making precision manufacturing non-negotiable.

Selecting the Right Landing Gear System

| Trailer Type | Gear Type | Capacity | Coating | Key Benefit |

|---|---|---|---|---|

| Freight Trailer | Dual-Speed Gearbox | 50,000 lbs | Zinc | Smooth control & strength |

| Tanker Trailer | Drop-Leg Dual Gear | 70,000 lbs | HDG | Reliable under extreme loads |

| Construction Fleet | Single-Speed Heavy Jack | 40,000 lbs | Epoxy | Simplified structure & low wear |

| Agricultural Trailer | Compact Manual Gear | 25,000 lbs | Powder | Light, fast lift |

| OEM Partner Build | Custom Configuration | Variable | Custom | Fit-for-purpose integration |

Zhongteli collaborates directly with OEM clients to match lifting speed, mounting pattern, and operational torque requirements — ensuring complete mechanical harmony with each trailer chassis.

Frequently Asked Questions

Q1: What materials are used in Zhongteli landing gear?

Forged alloy steel with heat treatment for maximum durability.

Q2: How often should landing gear be maintained?

Every 6 months under heavy operation; Zhongteli’s lubricated gears reduce this need significantly.

Q3: Are customized models available?

Yes — Zhongteli offers OEM service with branding, finish, and specification customization.

Q4: Can the system be used in cold or marine environments?

Absolutely. Coatings like hot-dip galvanization ensure long-term corrosion resistance.

A Foundation You Can Trust

A trailer’s stability is its foundation — and that foundation begins with the landing gear.

Zhongteli’s trailer landing gear systems are designed not only to support weight but to secure confidence — every mile, every load, every day.

Discover engineered stability at Zhongteli’s homepage or contact us here to explore OEM partnerships and bulk supply options.