Understanding Torsion Axles and Their Importance

Torsion axles represent a significant advancement in suspension technology, utilizing the twisting properties of rubber or other resilient materials to absorb shocks and vibrations. Unlike traditional leaf spring systems, torsion axles provide a smoother ride by distributing weight more evenly across the axle. As a dedicated torsion axle manufacturer, we focus on designing these axles to handle heavy loads without compromising on flexibility or longevity. This design is particularly beneficial in off-road conditions or when towing, where stability is paramount. Our manufacturing process involves precision machining and quality control measures that ensure each axle can withstand extreme stresses, reducing wear and tear on connected components.

The evolution of torsion axles dates back to the mid-20th century, but modern innovations have elevated their performance to new heights. In our facility, we employ state-of-the-art CAD software and finite element analysis to simulate real-world scenarios, allowing us to refine designs before production. This approach not only enhances the axle's load-bearing capacity but also minimizes maintenance requirements. For industries ranging from agriculture to marine transport, partnering with a reliable torsion axle manufacturer ensures compliance with safety regulations and optimal operational efficiency.

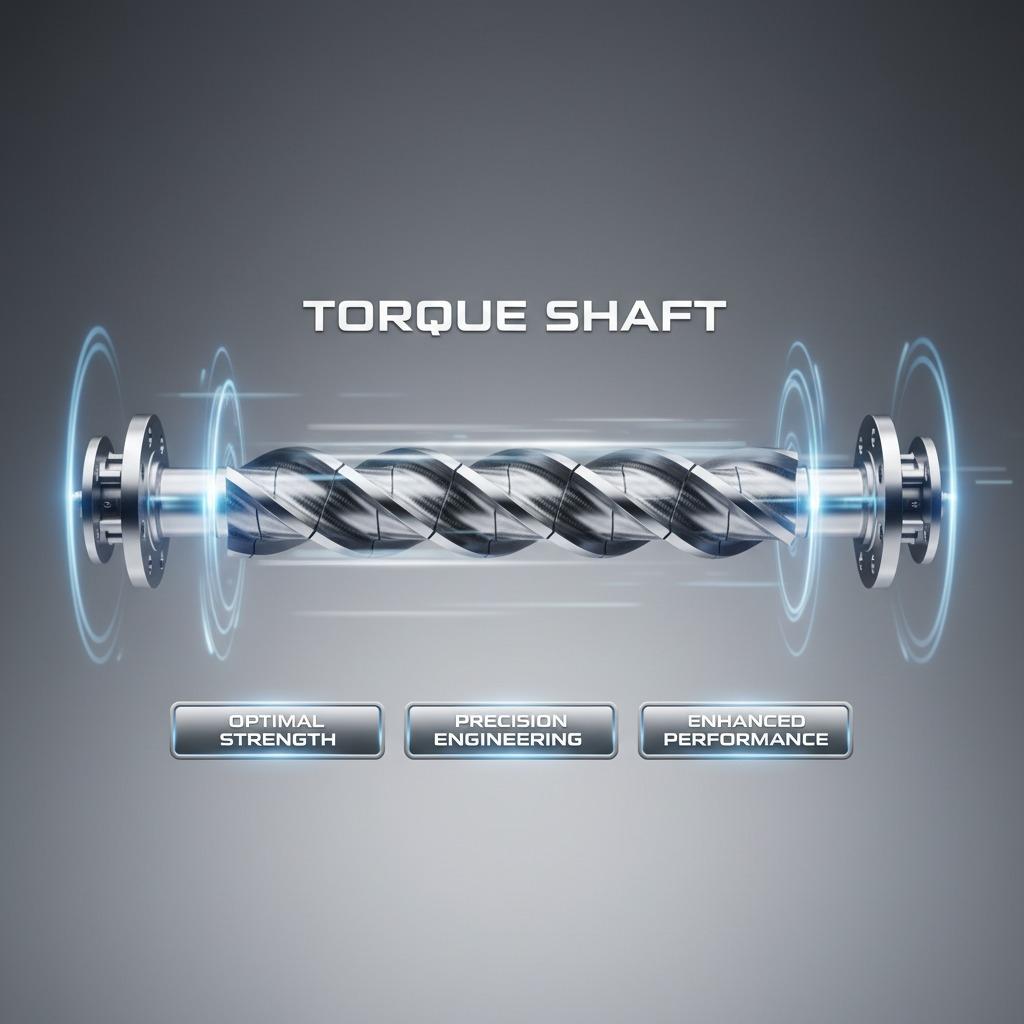

Introducing the Torque Shaft: A Game-Changer from Our Lineup

At the heart of our product offerings is the Torque Shaft, the epitome of cutting-edge engineering designed for optimal strength and precision. This high-performance component is crafted to deliver unparalleled efficiency in motion transfer, making it an essential upgrade for any system requiring robust power transmission. With its sleek, robust design, the Torque Shaft ensures maximum durability and reliability in demanding applications, seamlessly integrating with torsion axle setups to enhance overall functionality.

As a torsion axle manufacturer committed to innovation, we have engineered the Torque Shaft from top-grade materials that resist corrosion and fatigue even under prolonged use. Its precision-machined surfaces allow for perfect alignment, reducing energy loss and operational noise. Whether incorporated into trailer suspensions or heavy-duty vehicles, this component elevates the performance of torsion axles by providing consistent torque distribution. Our team of engineers draws on years of experience to customize the Torque Shaft for specific load requirements, ensuring it fits seamlessly into your existing infrastructure.

Key Features of the Torque Shaft

Optimal strength is the cornerstone of the Torque Shaft, engineered from high-tensile alloys and composite reinforcements that provide exceptional resilience and a long lifespan. This feature alone sets it apart in the competitive landscape of mechanical components, allowing it to endure impacts that would compromise lesser designs. As a torsion axle manufacturer, we prioritize materials that not only meet but exceed industry benchmarks, such as those set by ASTM standards for load capacity and fatigue resistance.

Precision engineering defines the Torque Shaft's core, with every element meticulously crafted for accurate alignment and smooth operation. This minimizes vibration, which can lead to premature wear in surrounding parts, and enhances overall efficiency by ensuring power is transferred without slippage. In high-torque environments, such as those found in construction equipment or marine propulsion systems, this precision translates to reduced downtime and lower operational costs. Our quality assurance process includes rigorous testing, including torque simulation and endurance cycling, to verify that each unit performs flawlessly.

Enhanced performance is another hallmark, as the Torque Shaft is designed to boost overall system dynamics. It ensures seamless power transmission, making it ideal for applications where every ounce of efficiency counts. From recreational boating to agricultural hauling, the Torque Shaft integrates effortlessly with torsion axles, amplifying their shock-absorbing capabilities while maintaining directional stability. As a leading torsion axle manufacturer, we back this performance with comprehensive warranties and technical support to guide installation and maintenance.

Applications and Benefits in Real-World Scenarios

The versatility of the Torque Shaft shines in diverse applications, particularly when paired with torsion axles in trailer manufacturing. For instance, in the RV industry, it provides a stable base that improves towing safety on highways and rugged terrains alike. By absorbing torsional forces effectively, it prevents axle misalignment, which can cause uneven tire wear or handling issues. As a torsion axle manufacturer, we have seen firsthand how this component extends the service life of entire suspension systems, often by 30-50% compared to traditional setups.

In industrial contexts, such as mining or logging operations, the Torque Shaft's durability under heavy loads is invaluable. It handles dynamic stresses from uneven ground without faltering, ensuring continuous productivity. Benefits extend beyond mechanics to include fuel efficiency gains, as smoother operation reduces drag and resistance. Environmental considerations are also addressed through our eco-friendly manufacturing practices, using recyclable materials that minimize waste. Clients appreciate how our torsion axle solutions, enhanced by the Torque Shaft, contribute to sustainable operations without sacrificing performance.

For marine applications, the Torque Shaft's corrosion-resistant coatings make it suitable for saltwater exposure, a common challenge for boat trailers. This feature, combined with the inherent flexibility of torsion axles, allows for easy launching and retrieval without structural damage. Overall, the benefits encompass improved safety, cost savings on repairs, and enhanced user comfort, positioning our products as top choices for professionals and enthusiasts alike.

Why Partner with Us as Your Torsion Axle Manufacturer

Choosing the right torsion axle manufacturer can transform your project outcomes, and we stand out through our commitment to customization and customer service. From initial consultation to post-sale support, our experts collaborate to tailor solutions like the Torque Shaft to your exact specifications. We invest heavily in R&D to stay ahead of trends, such as lightweight designs that comply with evolving emissions standards. Our ISO-certified facility ensures traceability and consistency in every batch produced.

Beyond technical prowess, we foster long-term partnerships by offering educational resources, including webinars on torsion axle maintenance and Torque Shaft integration. This holistic approach not only builds trust but also empowers our clients to maximize their investments. In an industry where reliability is non-negotiable, our track record of zero-defect deliveries speaks volumes. As your torsion axle manufacturer, we aim to be more than a supplier—we're a strategic ally in mechanical excellence.

Conclusion: Elevate Your Systems Today

In summary, as a torsion axle manufacturer at the forefront of innovation, we invite you to explore the Torque Shaft and discover how it can optimize your operations. With its superior strength, precision, and performance, this component is poised to set new standards in motion transfer and suspension technology. Contact us to discuss your needs and experience the difference that quality engineering brings. Upgrading to our solutions isn't just an investment—it's a step toward unparalleled reliability and efficiency in every turn.