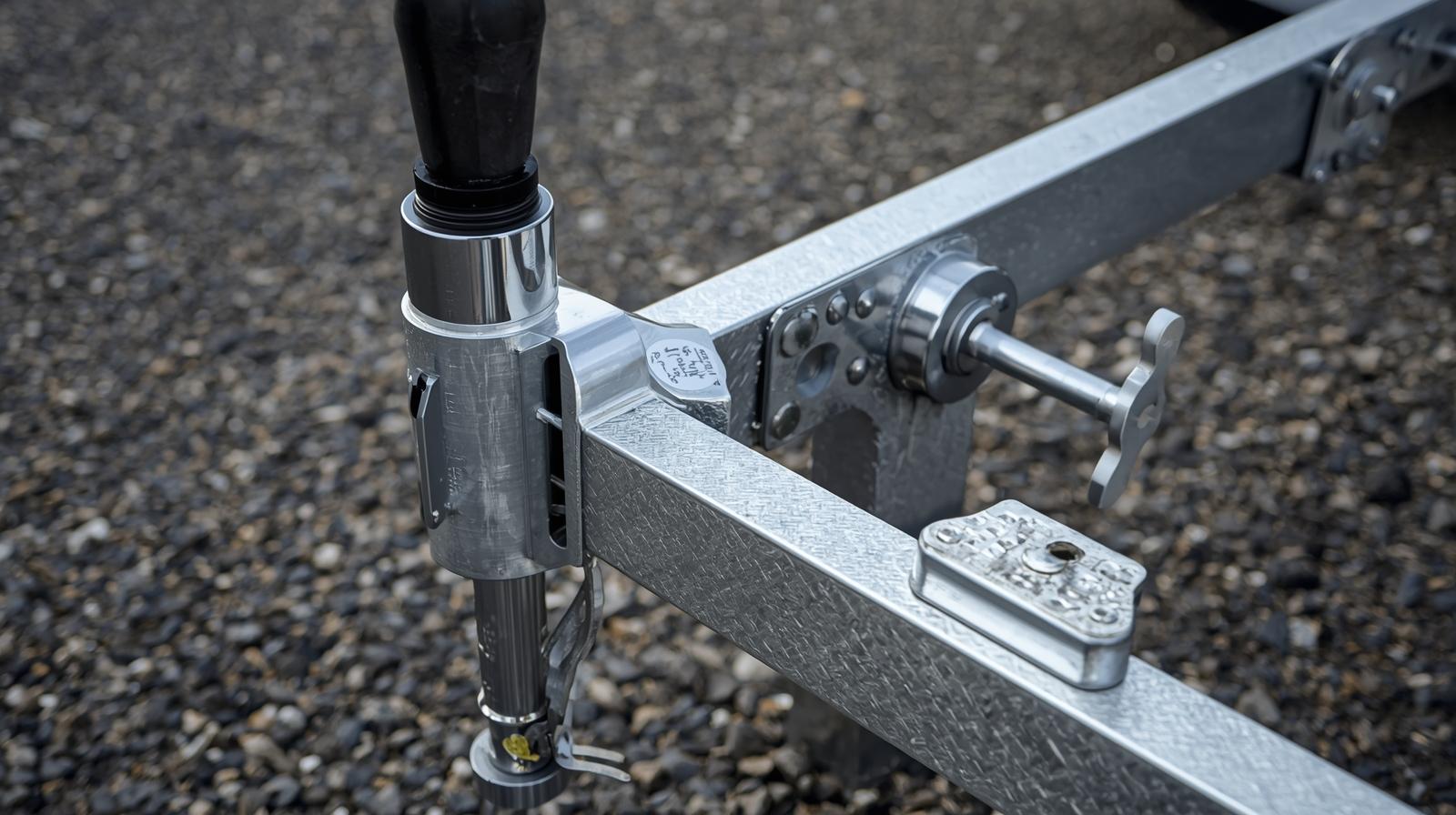

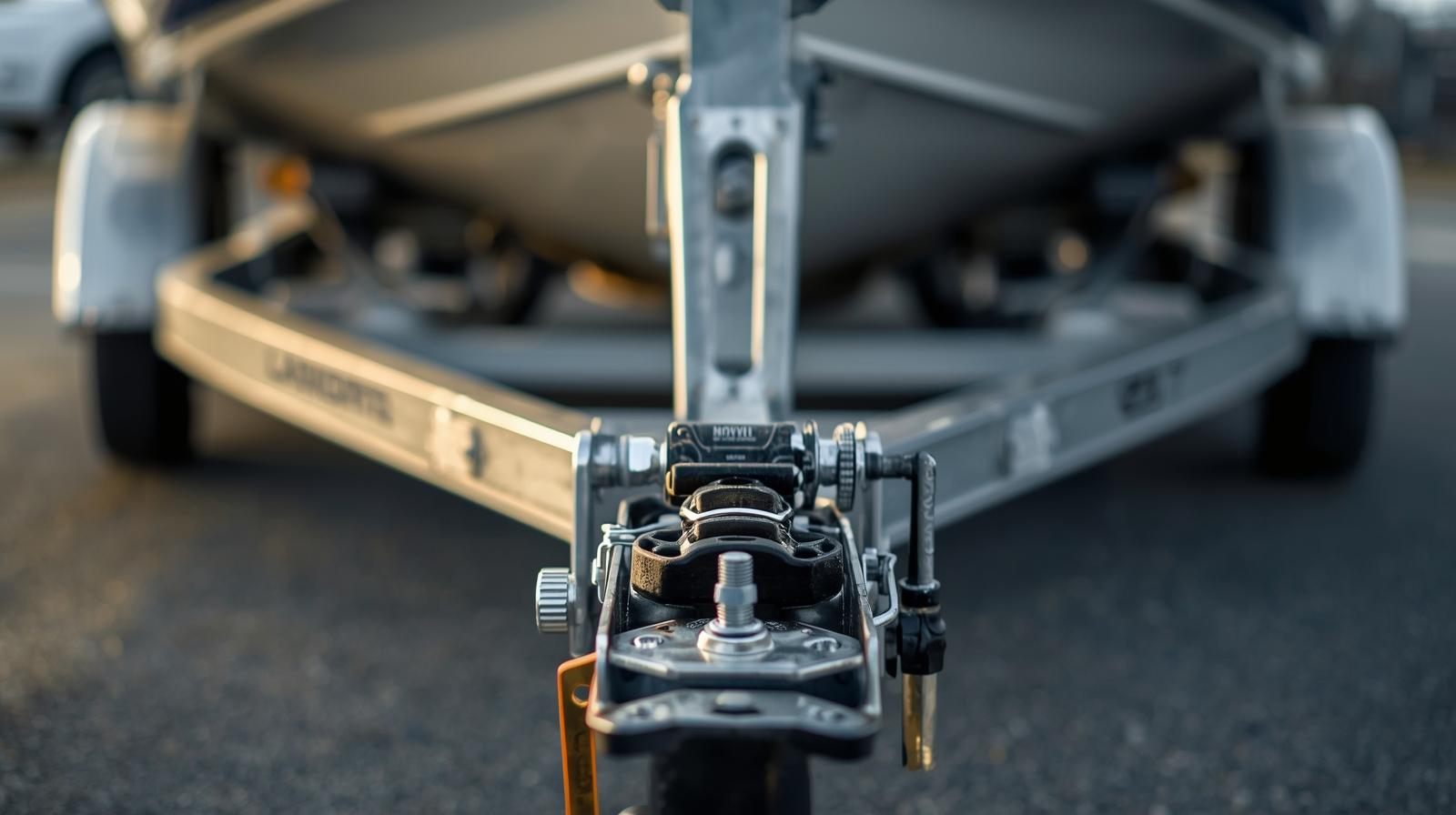

Marine Trailer Jack OEM: Built for Strength and Corrosion Resistance on the Water

Transporting boats or marine equipment demands specialized trailer components that can withstand constant saltwater exposure, heavy weight, and unpredictable terrain.

A regular trailer jack simply can’t survive the corrosion, rust, or vibration caused by coastal conditions.

That’s why Zhongteli, a professional marine trailer jack OEM manufacturer, designs and produces heavy-duty jacks tailored for marine transport and boat handling — combining forged strength with marine-grade coatings for unmatched durability.

The Demands of Marine Trailer Applications

Marine trailers face three major challenges: corrosion, instability, and mechanical wear.

Standard jacks exposed to seawater often rust within months, compromising lifting performance and operator safety.

Core Functional Requirements of Marine Jacks:

-

Corrosion Resistance: Zinc, epoxy, or galvanic coatings protect against salt exposure.

-

Forged Steel Structure: Provides resistance to deformation under heavy loads.

-

Drainage Design: Prevents trapped water and rust formation inside housing.

-

Sealed Bearings: Keep sand and salt from entering the screw mechanism.

-

Stainless Hardware: Adds extended durability for long-term use.

As noted by SAE International, corrosion-resistant steel treatments increase marine hardware lifespan by up to 300% in high-humidity environments.

Marine-Grade vs. Standard Trailer Jacks

| Feature | Marine Trailer Jack | Standard Trailer Jack |

|---|---|---|

| Material | Forged Steel / Stainless Alloy | Mild Steel |

| Coating | Zinc + Epoxy / Hot-Dip Galvanized | Painted |

| Corrosion Resistance | High (Saltwater Tested) | Moderate |

| Maintenance Need | Low | Frequent Lubrication |

| Primary Use | Boat, Coastal & Dock Transport | Land Transport |

A marine-grade trailer jack must not only lift, but endure exposure to seawater, rain, and UV — areas where standard trailer jacks often fail within one season.

Zhongteli’s OEM Production Capabilities

Zhongteli integrates forging, CNC machining, and surface finishing to produce marine-grade trailer jacks that meet OEM quality demands for international brands.

OEM Strengths:

-

Forged Base Plate and Tube: Dense metal structure resists bending and vibration.

-

Marine Coatings: Epoxy or hot-dip galvanized finishes tested for 1000+ salt spray hours.

-

Custom Mounting Options: Side-mount, top-mount, or swing-up types for boat trailers.

-

Sealed Gear Systems: Lubricated for smooth torque even under pressure.

-

Brand Customization: Handle grips, label color, and logo engraving available.

Every batch is tested to comply with ISO 9001, CE, and EN 12195-3 export standards — ensuring Zhongteli’s OEM clients receive globally certified marine jacks.

Real-World Marine Applications

Zhongteli’s marine trailer jacks are used in challenging conditions where water, salt, and mud meet steel.

Key use cases include:

-

Boat Trailers: Provides stable lifting during docking and transport.

-

Coastal Equipment Trailers: Handles moisture, vibration, and uneven terrain.

-

Dockside Cradles: Supports heavy hulls or fishing boats during maintenance.

-

Harbor Utility Carts: Assists in moving generators and marine gear safely.

-

OEM Manufacturing Lines: Integrated into custom boat trailer systems for export.

Safety compliance is ensured through the National Highway Traffic Safety Administration (NHTSA) guidelines for load and towing safety.

Selecting the Right Marine Trailer Jack

| Marine Environment | Jack Type | Coating | Load Capacity | Key Benefit |

|---|---|---|---|---|

| Coastal Boat Trailer | Top Wind Marine Jack | Zinc + Epoxy | 5,000 lbs | Fast deployment and strong corrosion protection |

| Saltwater Harbor | Swing-Up Marine Jack | Hot-Dip Galvanized | 3,000 lbs | Compact design, easy storage |

| Boat Maintenance Dock | Drop Leg Jack | Powder Coat | 7,000 lbs | Added stability for uneven surfaces |

| OEM Assembly Line | Custom Forged Jack | Custom Finish | Variable | Branding and dimension flexibility |

Zhongteli’s technical team provides OEM clients with design consultation to match the right coating, torque range, and mounting configuration to each marine environment.

Asked Questions

Q1: What makes a trailer jack suitable for marine use?

It must use anti-corrosion coatings and sealed components to withstand moisture and salt exposure.

Q2: How long does Zhongteli’s marine coating last?

Epoxy and galvanized coatings have passed 1000-hour salt spray tests with minimal rust.

Q3: Can Zhongteli produce OEM marine jacks under private labels?

Yes, Zhongteli provides full OEM services — including color, logo, and handle customization.

Q4: What is the average production lead time?

Approximately 25–35 days, depending on customization and coating type.

Built to Last Where Steel Meets Salt

A marine trailer jack is more than a lifting tool — it’s a critical part of boat safety and transport stability.

With forged steel strength and marine-grade protection, Zhongteli ensures long service life even in the harshest coastal conditions.

From dockside loading to long-distance boat hauling, Zhongteli’s OEM jacks combine power, corrosion resistance, and trusted reliability.

Learn more at Zhongteli’s homepage or contact us here for OEM cooperation and bulk orders.