Trailer Support Leg Manufacturer: Strong Foundations for Heavy Loads

When a trailer stands still, its stability depends entirely on the support legs beneath it.

From cargo trailers to farm equipment, a small imbalance can cause dangerous tilting or frame stress.

That’s why Zhongteli, a leading trailer support leg manufacturer, builds forged steel support systems engineered for safety, balance, and long service life under extreme loads.

The Role of Trailer Support Legs in Load Stability

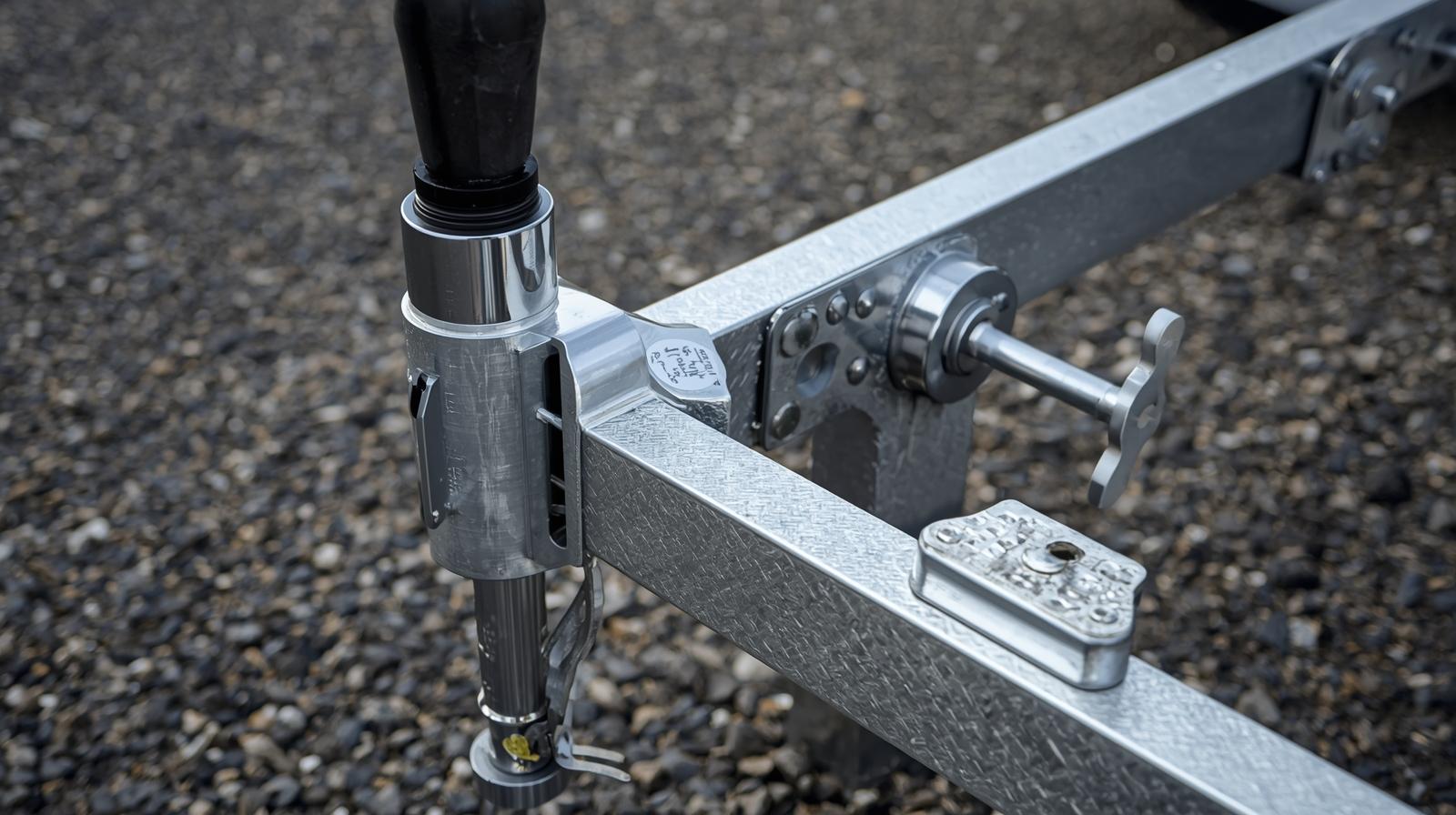

A support leg—often called landing gear or a stabilizer—is designed to bear the trailer’s full front-end load when uncoupled.

Without it, the trailer’s center of gravity shifts forward, leading to tipping, jack-knifing, or structural fatigue.

Core Mechanical Principles:

-

Vertical Load Distribution: Transfers weight safely from chassis to ground.

-

Dual Leg Synchronization: Keeps both sides balanced during deployment.

-

Adjustable Height Mechanism: Adapts to different terrain levels.

-

Reinforced Base Plates: Prevents sinkage on soft ground.

-

Corrosion Resistance: Coatings protect steel integrity in all climates.

As explained by SAE International, properly designed trailer landing gear systems significantly reduce coupling stress and improve cargo safety across transport fleets.

Trailer Support Legs vs. Standard Jacks

| Feature | Trailer Support Leg | Standard Trailer Jack |

|---|---|---|

| Load Capacity | Up to 50 tons (dual system) | Up to 10 tons |

| Application | Semi-trailers, heavy cargo, tankers | Light trailers, RVs |

| Structure | Dual-leg or telescopic | Single screw jack |

| Deployment | Manual or gear-driven | Manual crank only |

| Durability | Industrial-grade | Medium-duty |

Trailer support legs are built for commercial and industrial use, where stability under massive weight and repeated loading cycles is essential.

Zhongteli’s Manufacturing Capabilities

Zhongteli integrates forging, CNC machining, welding, and coating into a unified production line.

Every support leg is tested under simulated field conditions before shipment.

Production Advantages:

-

Forged Alloy Housing: Withstands vibration and shock.

-

Dual-Shaft Synchronization: Ensures even lifting and lowering.

-

Hot-Dip Galvanized Finish: Superior corrosion resistance.

-

High-Torque Gear System: Smooth operation under extreme loads.

-

OEM Customization: Adjustable height, handle design, and mounting plates available.

All Zhongteli support legs comply with ISO 9001, EN 12195-3, and CE certification standards, making them trusted globally by trailer builders and fleet operators.

Applications Across Trailer Industries

Zhongteli’s trailer support legs are used in multiple industries where safety and durability matter most:

-

Logistics & Freight Trailers: Keeps trailers level during cargo loading.

-

Construction Transport: Supports equipment trailers on uneven terrain.

-

Agricultural Implements: Provides stability for grain and farm machinery trailers.

-

Tanker and Flatbed Trailers: Handles heavy static loads safely.

-

OEM Manufacturing Lines: Integrated into custom trailer chassis designs.

The National Highway Traffic Safety Administration (NHTSA) emphasizes that load-bearing systems like support legs are critical for preventing trailer movement accidents during loading and maintenance.

Choosing the Right Support Leg for Your Fleet

| Trailer Type | Support Leg Model | Load Rating | Coating | Key Feature |

|---|---|---|---|---|

| Flatbed Trailer | Dual-Shaft Landing Gear | 20–30 tons | Zinc | Balanced lifting and long life |

| Cargo Trailer | Adjustable Telescopic Leg | 10–20 tons | Epoxy | Flexible height and easy operation |

| Agricultural Trailer | Heavy Duty Stabilizer Leg | 8–15 tons | Powder | Rust-resistant and field durable |

| Tanker Trailer | Reinforced Gear Leg | 30–50 tons | Galvanized | High load endurance |

| OEM Production | Custom Design | Variable | Custom | Branding and mounting flexibility |

Zhongteli provides engineering consultation for OEM partners, helping them select materials, torque settings, and finishes that fit specific operating environments.

Frequently Asked Questions

Q1: What’s the difference between a support leg and landing gear?

They refer to the same function — providing vertical load support for uncoupled trailers.

Q2: Are Zhongteli’s support legs suitable for tanker or flatbed trailers?

Yes, heavy-duty variants are designed for high-load and vibration resistance.

Q3: Does Zhongteli provide OEM or private-label production?

Absolutely. OEM customization is available for size, coating, and branding.

Q4: What is the typical delivery time?

Usually 30 days, depending on customization and coating requirements.

Supporting Stability, Driving Safety

A trailer support leg is the unsung hero of every transport fleet — ensuring safety when motion stops.

Zhongteli’s forged steel legs are built to withstand pressure, resist corrosion, and maintain balance through years of operation.

From logistics fleets to OEM trailer factories, Zhongteli delivers reliability where it matters most.

Learn more at Zhongteli’s homepage or contact us here for bulk supply and OEM partnership opportunities.