Side Wind Trailer Jack Factory: Reliable Lifting for Heavy-Duty Trailers

For anyone managing trailers, equipment transport, or industrial logistics, reliable lifting is non-negotiable.

A side wind trailer jack is designed to make raising and lowering heavy loads smooth, fast, and secure — keeping operations safe in every environment.

As a trusted side wind trailer jack factory, Zhongteli focuses on durability, usability, and performance, combining forged steel structure with smooth-turning gear design to ensure consistent lifting across daily use.

How Side Wind Trailer Jacks Work

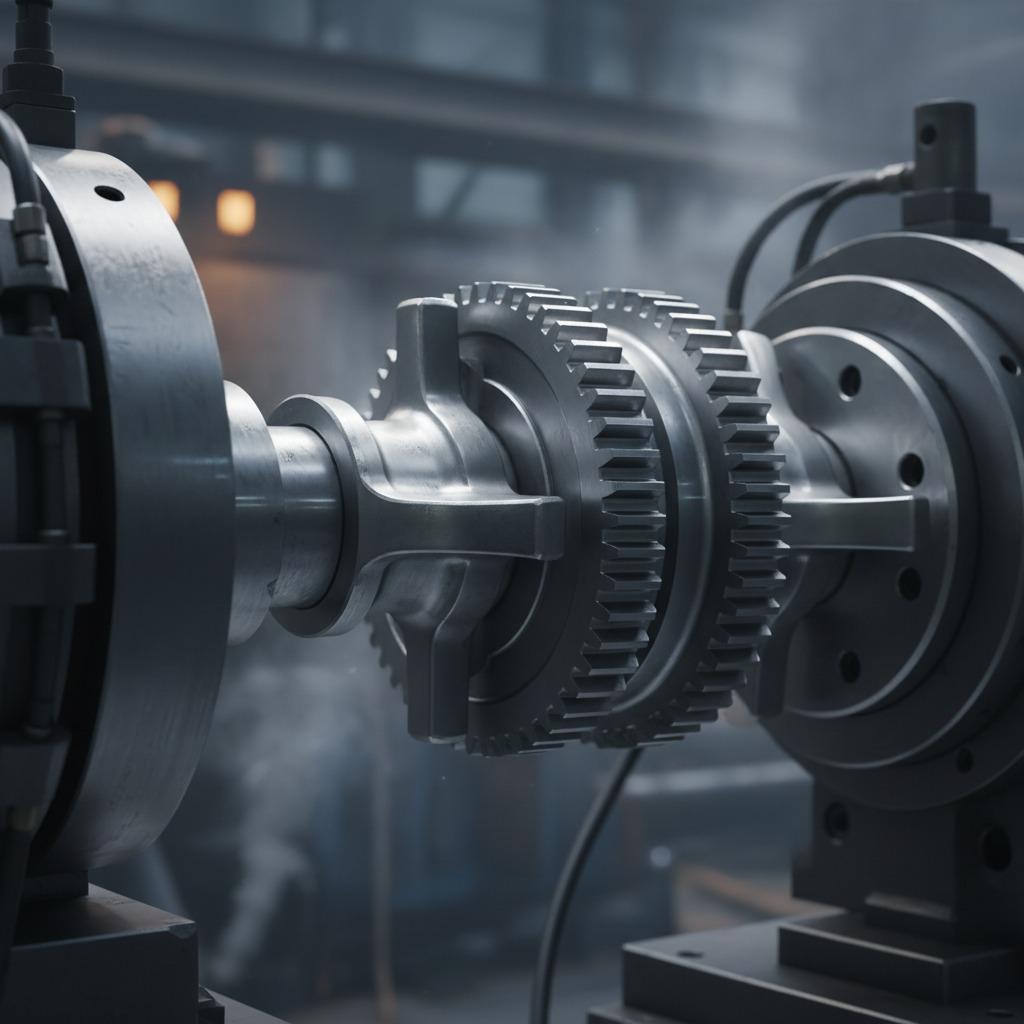

A side wind jack features a vertically mounted crank handle on the side of the jack housing, making it easier to operate when space is limited or when the trailer is attached to a vehicle.

The mechanical gear system transfers rotational motion into vertical movement, providing powerful lift with minimal manual effort.

Core Features of Zhongteli Side Wind Jacks:

-

Forged steel construction: Resists deformation and stress fatigue.

-

Grease-sealed gears: Ensures smooth operation and reduced maintenance.

-

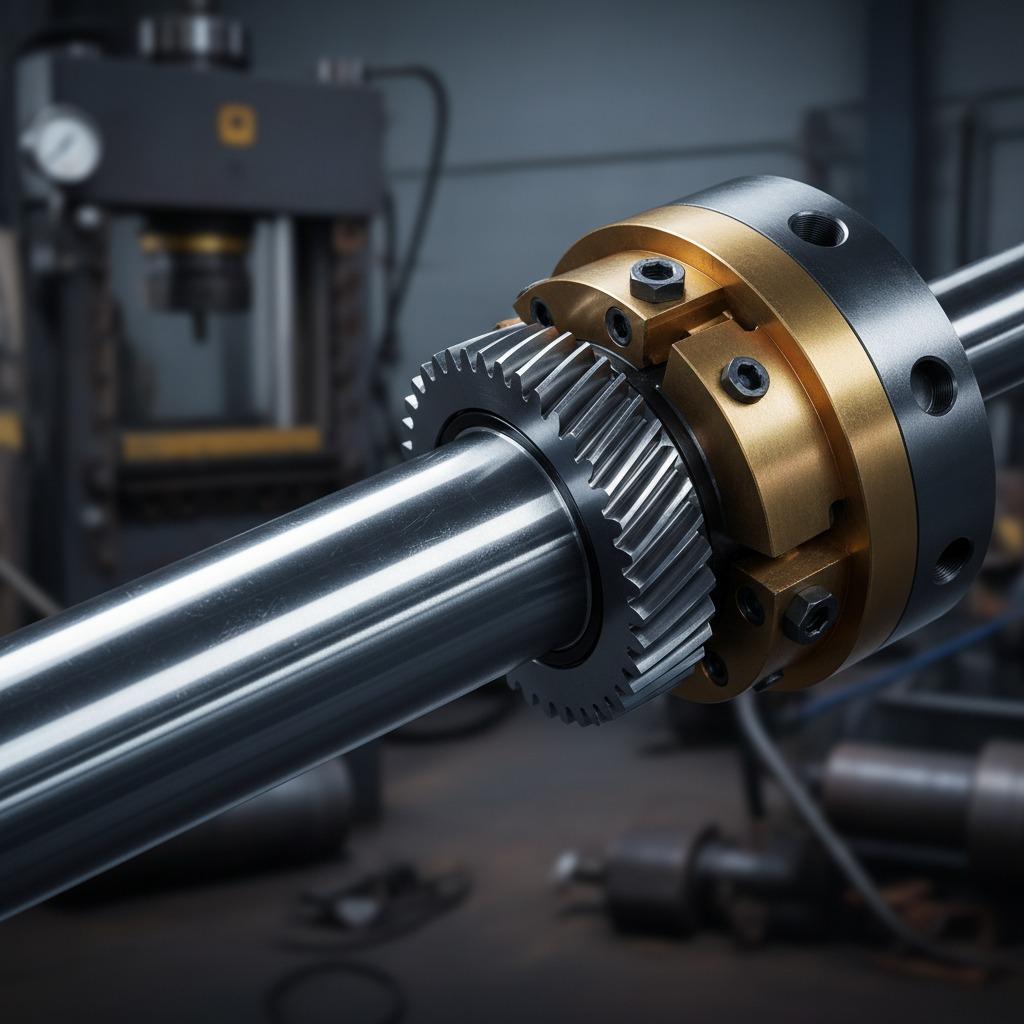

Heavy-duty screw shaft: Provides stable torque transmission.

-

Zinc or epoxy coating: Protects against corrosion, water, and road dust.

-

Compact side handle design: Ideal for tight working spaces.

The result — smooth, controlled lifting that meets the daily demands of transport and construction fleets.

Side Wind vs. Top Wind Jacks: Function and Performance

| Feature | Side Wind Jack | Top Wind Jack |

|---|---|---|

| Handle Position | Side of housing | On top of housing |

| Ease of Use | Convenient for attached trailers | Easier for open trailers |

| Best Application | Construction, utility, and tall trailers | Flatbeds and light utility trailers |

| Maintenance | Enclosed gears require less care | More exposed to dust |

| Durability | Reinforced internal housing | Slightly lighter head unit |

Side wind trailer jacks are ideal for heavy-duty trailers that require quick operation, minimal effort, and extended durability — exactly where Zhongteli’s forged products excel.

Zhongteli’s Factory Strengths in Jack Manufacturing

Zhongteli integrates forging, machining, coating, and testing within a single facility to ensure consistent quality and production efficiency.

Our Production Advantages:

-

Material Testing: High-grade alloy steel verified for tensile and fatigue limits.

-

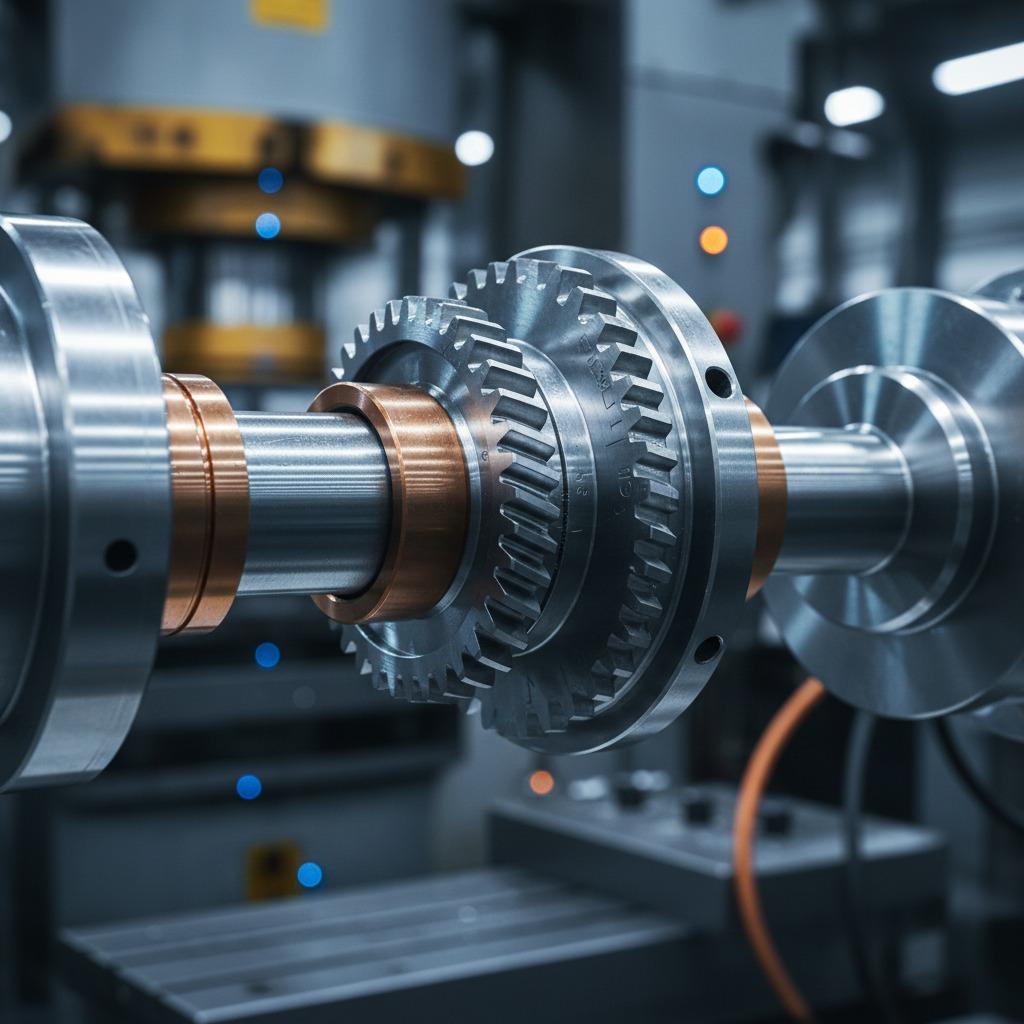

Closed-Die Forging: Strengthens molecular structure for long-term durability.

-

Precision Machining: ±0.05mm tolerance ensures stable gear engagement.

-

Surface Finishing: Zinc, epoxy, or powder coatings for rust resistance.

-

Batch Load Testing: Verifies working load limit (WLL) and torque balance.

With ISO-certified production and customizable OEM services, Zhongteli supports global brands seeking quality, consistency, and flexible supply capabilities.

Industrial Applications of Side Wind Trailer Jacks

Zhongteli’s side wind jacks are engineered for versatility across multiple industries and terrains:

-

Flatbed Trailers: Ensures stable support during long hauls.

-

Construction Equipment: Handles vibration and uneven surfaces on-site.

-

Agriculture: Resistant to dirt, dust, and moisture.

-

Marine Transport: Epoxy-coated versions prevent corrosion near saltwater.

-

OEM Integration: Custom-branded jacks for trailer assembly lines.

Wherever heavy loads demand reliability, Zhongteli products perform with strength and consistency.

Choosing the Right Side Wind Trailer Jack

Selecting the right jack depends on load capacity, mounting position, and working conditions.

| Trailer Type | Recommended Jack | Load Capacity | Coating | Advantage |

|---|---|---|---|---|

| Utility Trailer | Side Wind Jack | 2000–4000 lbs | Zinc | Compact and easy to handle |

| Heavy Equipment | Drop Leg Jack | 8000–10000 lbs | Powder Coat | Faster lifting, high torque |

| Construction Haulage | Dual Side Wind Jack | 10000+ lbs | Epoxy | Stable in high-vibration use |

| Coastal Operation | Marine-Grade Jack | 3000–7000 lbs | Epoxy | Long-term rust prevention |

| OEM Assembly | Custom Forged Jack | Variable | Any | Brand-specific configurations |

Zhongteli helps distributors and OEM clients match each product to its specific use case for maximum safety and efficiency.

Frequently Asked Questions

Q1: What’s the difference between manual and drop-leg models?

Drop-leg versions provide faster height adjustment with less cranking effort — ideal for frequent lifts.

Q2: Are Zhongteli side wind jacks suitable for export markets?

Yes, all products meet EN 12195-3, ISO 9001, and CE standards for lifting and safety.

Q3: Can the handle be customized for OEM brands?

Absolutely — Zhongteli offers custom handle lengths, coating colors, and logo engraving.

Q4: What’s the normal delivery time for international orders?

Standard production lead time is 25–30 days, depending on order volume and coating type.

Built for Power, Trusted for Performance

A side wind trailer jack is more than a support tool — it’s the foundation of every stable lift.

With forged strength, smooth operation, and corrosion-resistant design, Zhongteli ensures long-term reliability for manufacturers and fleet operators worldwide.

From heavy machinery to marine transport, Zhongteli jacks stand firm under every load.

Discover more on Zhongteli’s homepage or contact us here for OEM and wholesale inquiries.