Understanding Precision Torque Shafts

The torque shaft is a fundamental component in mechanical systems, responsible for transmitting rotational force with utmost accuracy. At a leading precision torque shaft factory, every shaft is meticulously designed to handle torque loads while maintaining structural integrity. These shafts are crafted from high-grade materials such as alloy steels or advanced composites, ensuring they can endure extreme conditions without deformation. The precision aspect comes from tight tolerances achieved through state-of-the-art machining processes, which minimize vibrations and enhance power transfer efficiency. For instance, in automotive applications, a well-made torque shaft can reduce energy loss by up to 15%, directly impacting fuel efficiency and overall machinery lifespan.

Beyond basic functionality, precision torque shafts are engineered to integrate seamlessly into complex assemblies. Factories specializing in this area employ computer-aided design (CAD) software to simulate real-world stresses, allowing for optimizations that generic components simply can't match. This level of detail ensures that each shaft not only meets but exceeds industry specifications, such as those outlined by ISO standards for mechanical power transmission. Whether for small-scale robotics or large industrial gearboxes, the role of a precision torque shaft factory in customizing these parts cannot be overstated, as it directly influences the reliability of end products.

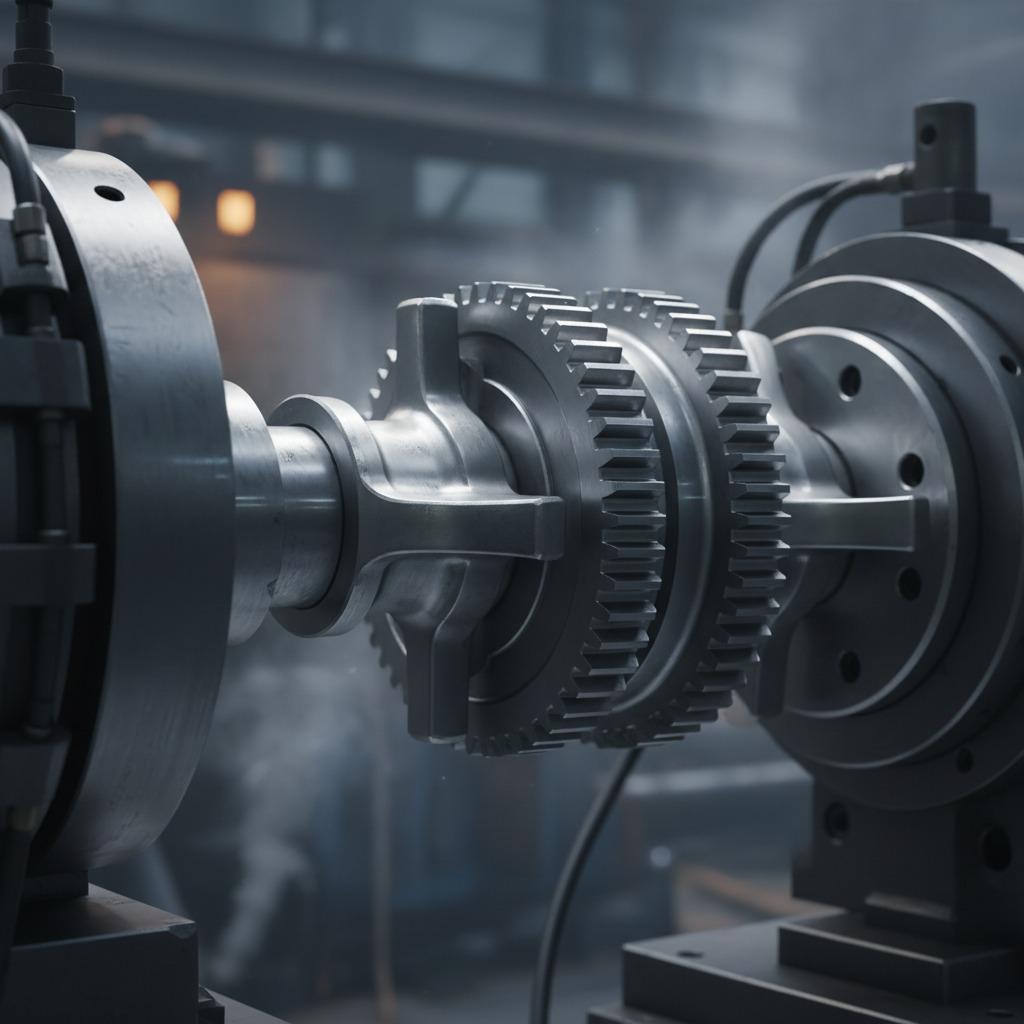

The Manufacturing Excellence at a Precision Torque Shaft Factory

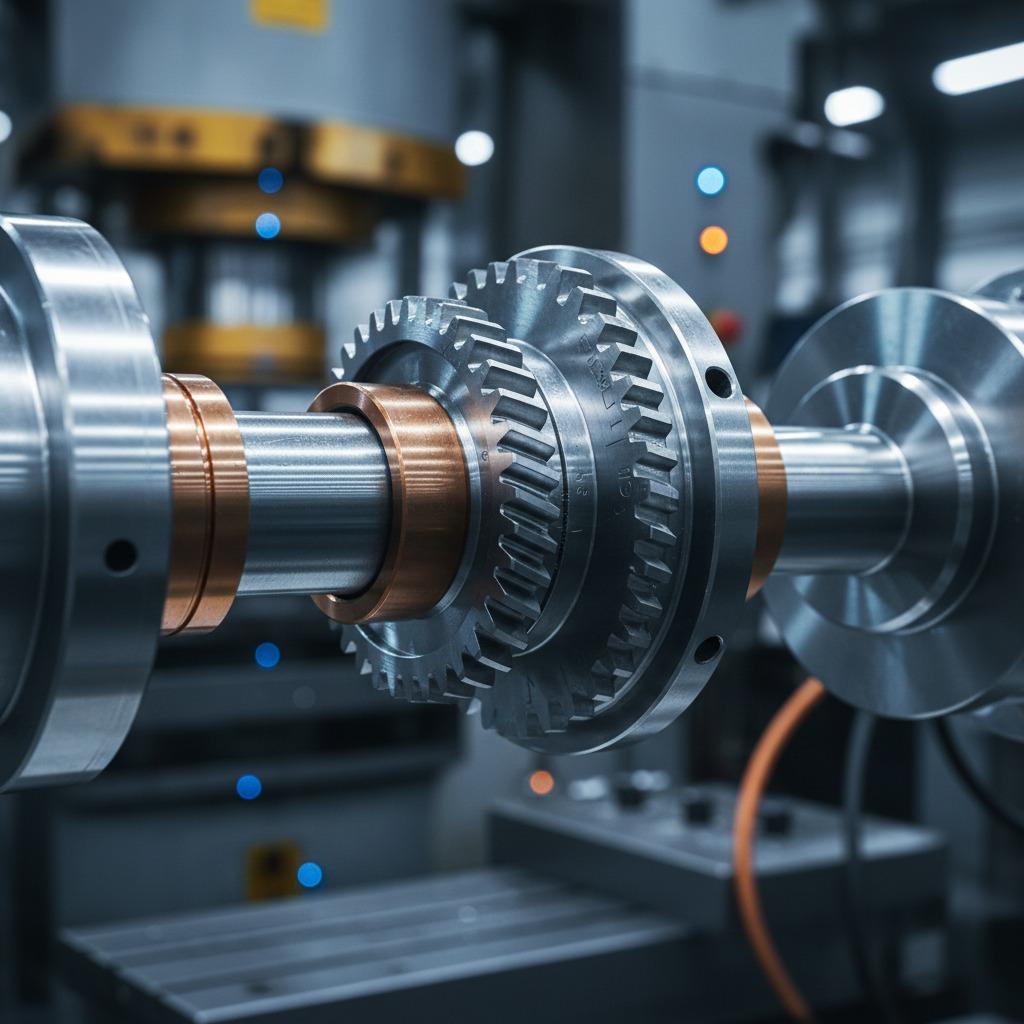

Entering the realm of a precision torque shaft factory reveals a symphony of advanced technology and skilled craftsmanship. The process begins with material selection, where raw billets are inspected for purity and strength to guarantee optimal performance. Heat treatment processes, including quenching and tempering, follow to impart the necessary hardness and ductility. CNC lathes and milling machines then shape the shafts to micron-level precision, removing any imperfections that could lead to failure under load.

Quality control is non-negotiable in such a facility. Each torque shaft undergoes non-destructive testing, like ultrasonic inspections, to detect internal flaws invisible to the naked eye. Surface finishing techniques, such as grinding and polishing, ensure smooth operation and reduced friction. At our factory, we incorporate lean manufacturing principles to streamline production, reducing waste while maintaining high output rates. This efficiency allows us to scale from prototype development to full-scale production without compromising on the precision that defines our torque shafts. Moreover, environmental considerations are woven into the process, with recycling programs for scrap metal and energy-efficient machinery that lower our carbon footprint.

Innovation drives the evolution of torque shaft manufacturing. Modern precision torque shaft factories invest in research and development to incorporate smart features, such as embedded sensors for real-time torque monitoring. These advancements not only enhance safety but also enable predictive maintenance, preventing costly downtimes. By staying ahead of trends like Industry 4.0, factories ensure their products remain relevant in a rapidly changing industrial landscape.

Key Benefits of Sourcing from a Precision Torque Shaft Factory

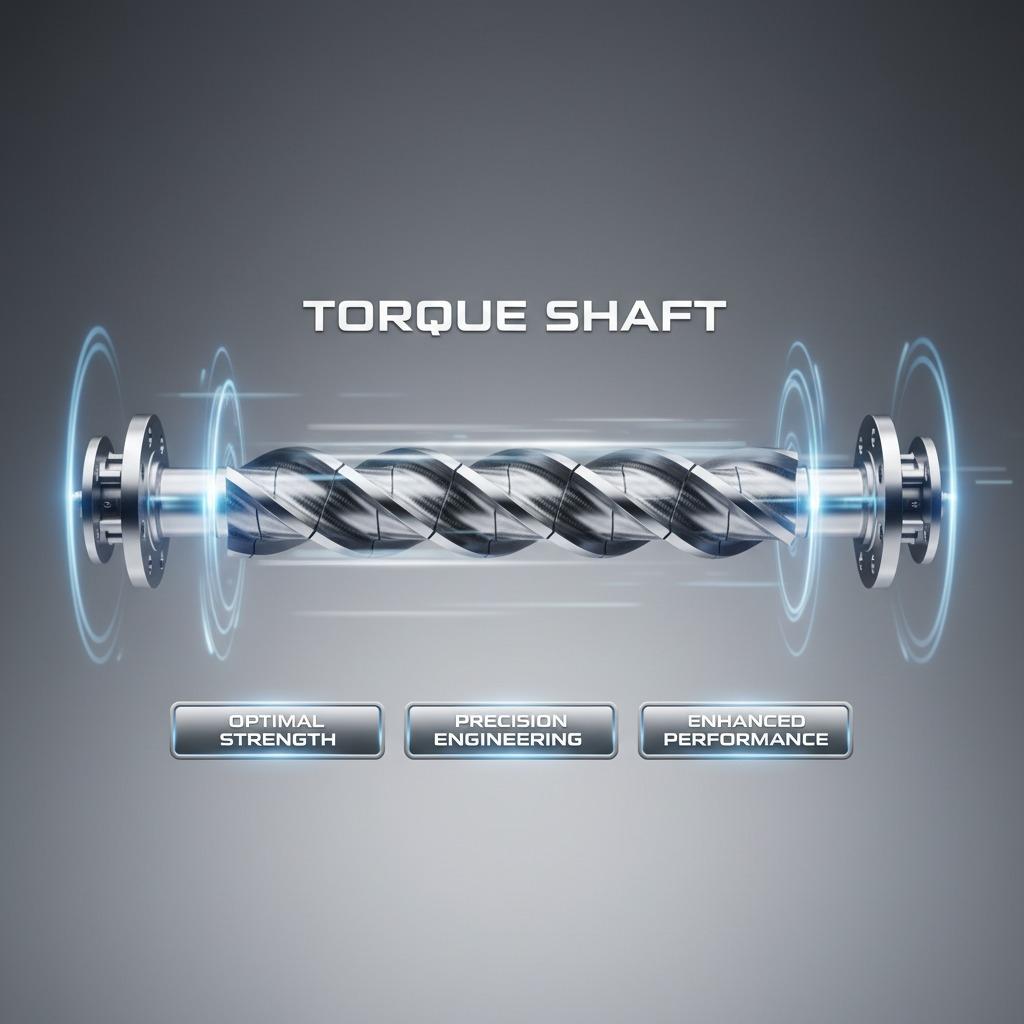

Optimal strength is a hallmark of torque shafts produced in a dedicated precision torque shaft factory. These components are built to withstand substantial stress, often rated for torques exceeding 10,000 Nm, making them ideal for heavy-duty applications in construction equipment or wind turbines. Durability translates to longevity, with many shafts lasting over a decade in continuous operation, far outpacing off-the-shelf alternatives.

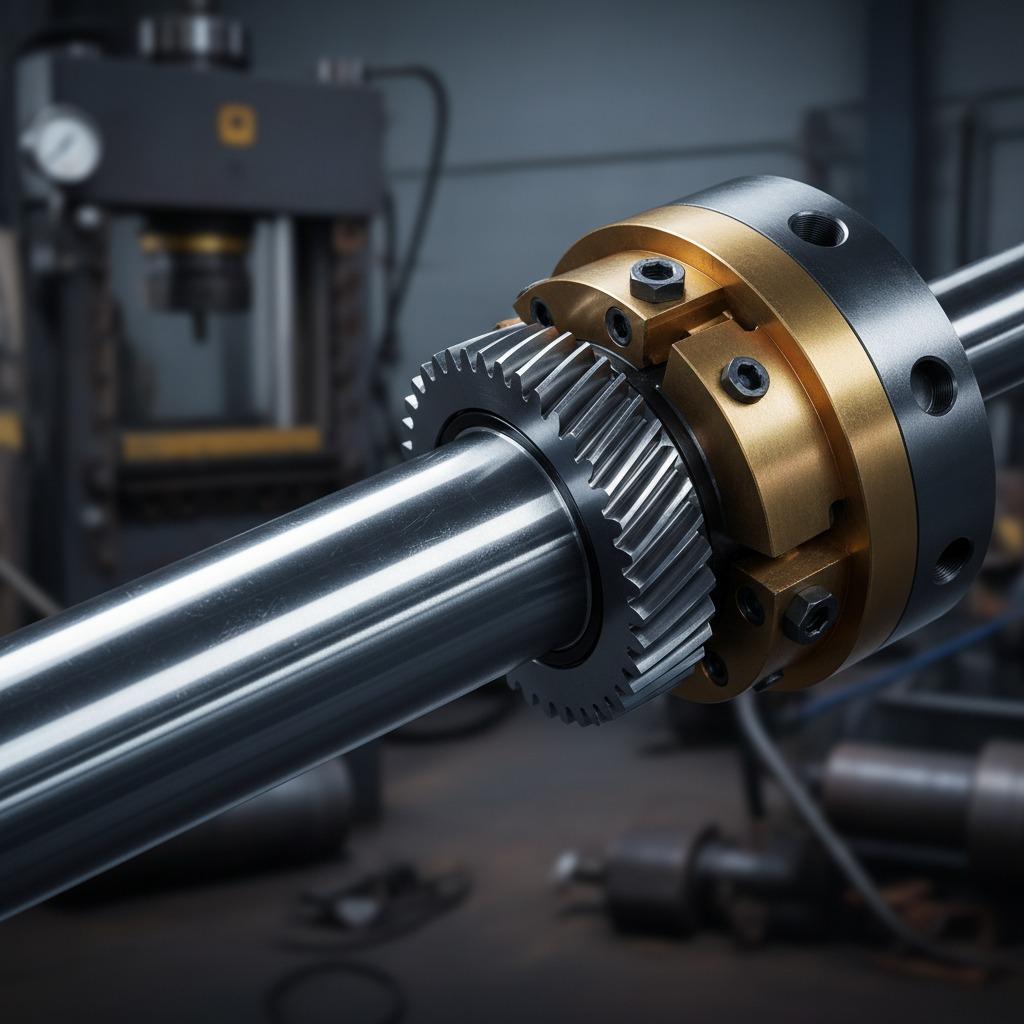

Precision engineering elevates these shafts beyond mere functionality. Superior accuracy in alignment and balance minimizes operational noise and wear on connected parts, leading to smoother power transmission with minimal energy loss. In high-speed environments, this precision can prevent catastrophic failures, safeguarding both equipment and personnel. Factories achieve this through rigorous metrology, using tools like coordinate measuring machines (CMMs) to verify dimensions down to the thousandth of an inch.

Enhanced performance is another compelling advantage. By maximizing efficiency, precision torque shafts reduce energy consumption while boosting output, which is crucial for industries aiming to meet sustainability goals. For example, in electric vehicle drivetrains, our shafts contribute to regenerative braking systems that recover up to 20% more energy. Partnering with a precision torque shaft factory means accessing customized solutions that align with your specific needs, whether it's corrosion-resistant coatings for marine applications or lightweight designs for aerospace.

Applications Across Diverse Industries

The versatility of torque shafts from a precision torque shaft factory spans numerous sectors. In the automotive industry, they form the backbone of transmission systems, ensuring reliable power delivery from engine to wheels. Aerospace demands even higher precision, where our shafts are used in actuator mechanisms for flight controls, enduring vibrations and temperature extremes at altitudes above 30,000 feet.

Heavy machinery, such as excavators and cranes, relies on these shafts for torque multiplication, enabling precise control in demanding terrains. In renewable energy, wind turbine gearboxes incorporate custom torque shafts to handle variable wind loads, optimizing energy capture. Even in consumer electronics, miniaturized versions drive robotic arms in assembly lines, showcasing the scalability of precision manufacturing.

Emerging fields like robotics and automation further highlight the importance of a specialized factory. Here, torque shafts must provide both high torque density and quick response times, facilitating agile movements in collaborative robots. By tailoring designs to these applications, precision torque shaft factories support innovation, from surgical robots in healthcare to autonomous vehicles in logistics.

Why Choose Our Precision Torque Shaft Factory?

Selecting the right precision torque shaft factory is about more than just product quality; it's about building a partnership that fosters growth. Our facility combines decades of expertise with cutting-edge technology, delivering shafts that embody strength, precision, and performance. We offer comprehensive services, from design consultation to just-in-time delivery, ensuring your projects stay on track.

Commitment to customer satisfaction drives us. With a track record of serving Fortune 500 companies, we understand the nuances of global supply chains and regulatory compliance. Our torque shafts have powered breakthroughs in efficiency, earning accolades for reliability in rigorous testing environments. By choosing us, you gain a collaborator dedicated to your success, providing not just components but solutions that propel your business forward.

In conclusion, the precision torque shaft factory landscape is defined by innovation and reliability, and we're proud to lead in this space. As industries push boundaries, our expertly crafted shafts continue to deliver the fusion of strength and precision needed for tomorrow's challenges. Contact us today to explore how our torque shafts can enhance your operations.

(Word count: 1028)