Mechanical Trailer Jack: Reliable Manual Power for Heavy Loads

When you need lifting power without complex hydraulics, a mechanical trailer jack delivers simplicity, strength, and control.

Built for demanding users, it turns manual motion into lifting force through precision-engineered gears and screw threads — dependable, even when automation fails.

Zhongteli, a trusted name in forged trailer components, develops mechanical trailer jacks engineered for reliability, safety, and smooth manual operation across cargo, agricultural, and utility trailers.

Why Choose Mechanical Jacks Over Hydraulic Ones

While hydraulic systems are powerful, they’re not always ideal for every environment. Mechanical jacks offer predictable performance — no fluid leaks, no maintenance cycles, and no pressure loss.

Common Problems in Hydraulic Systems:

-

Fluid leakage under pressure

-

Seal deterioration due to heat or dirt

-

Slow response in cold conditions

-

Complex repair and maintenance

Mechanical jacks avoid all these issues with gear-and-screw mechanics that convert torque into controlled lift. According to SAE International mechanical transmission principles, screw-driven systems maintain torque stability and consistent load distribution — crucial for heavy-duty trailer use.

Mechanical vs. Hydraulic Trailer Jacks

| Feature | Mechanical Trailer Jack | Hydraulic Trailer Jack |

|---|---|---|

| Power Source | Manual crank | Fluid pressure |

| Maintenance | Minimal | Requires regular service |

| Lifting Speed | Moderate, controlled | Faster but complex |

| Reliability | High in rough environments | Sensitive to damage |

| Best Use | Industrial and outdoor trailers | High-end vehicle lifts |

For most transport and farming users, mechanical trailer jacks deliver better reliability at lower operational costs — and can keep working even in remote locations.

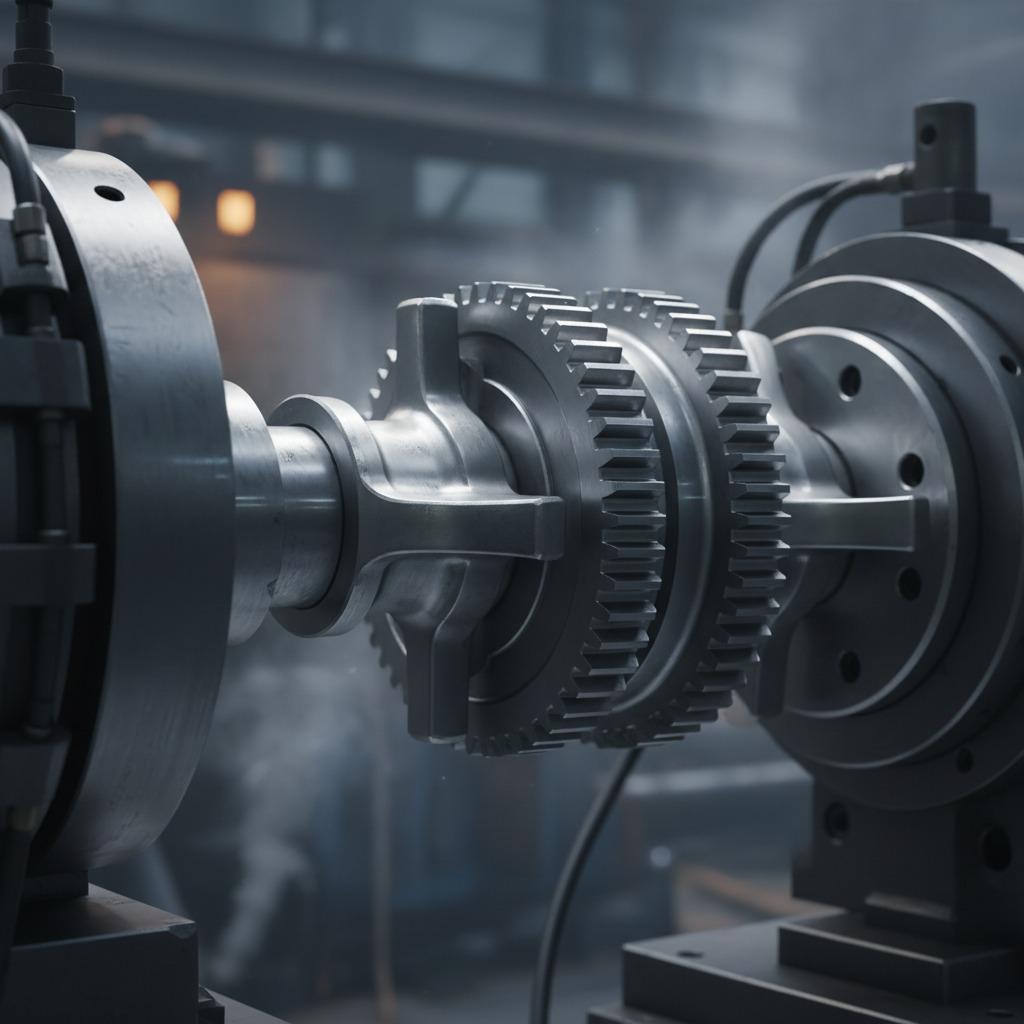

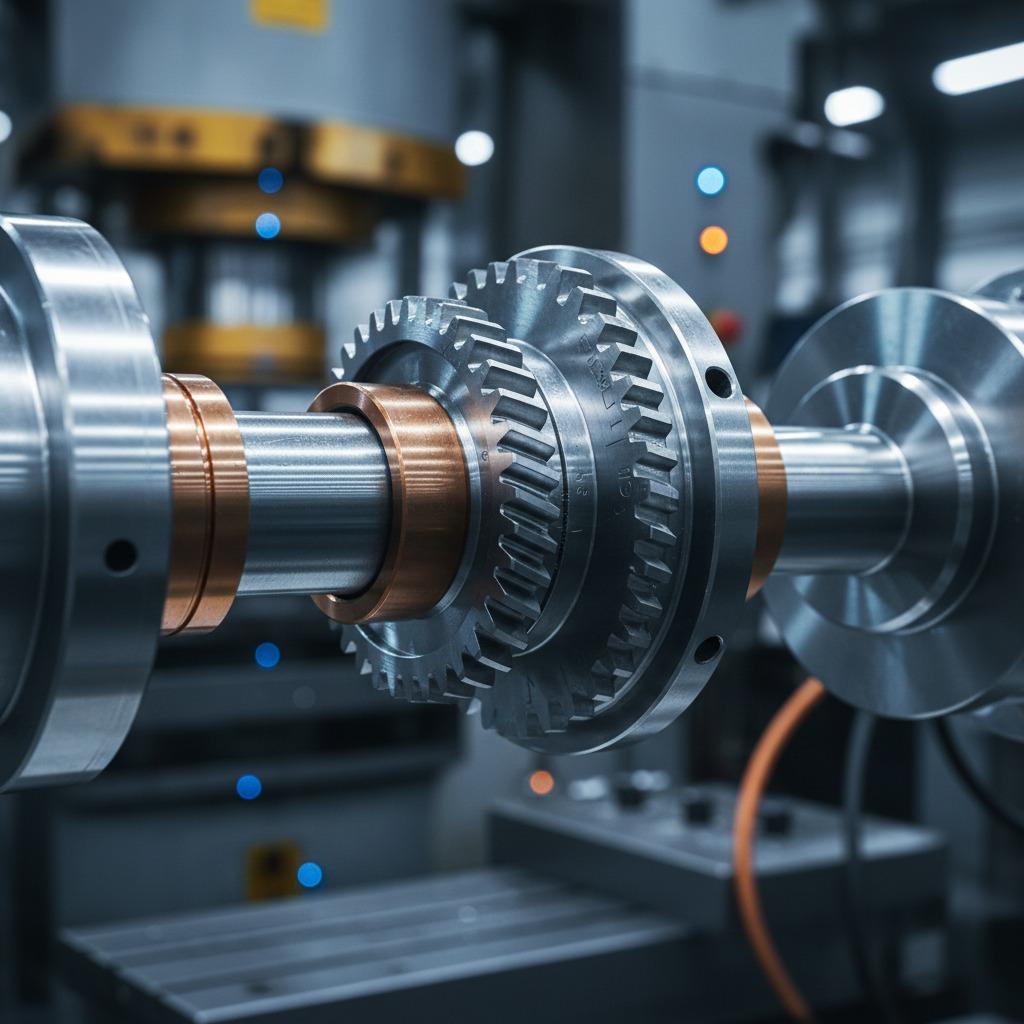

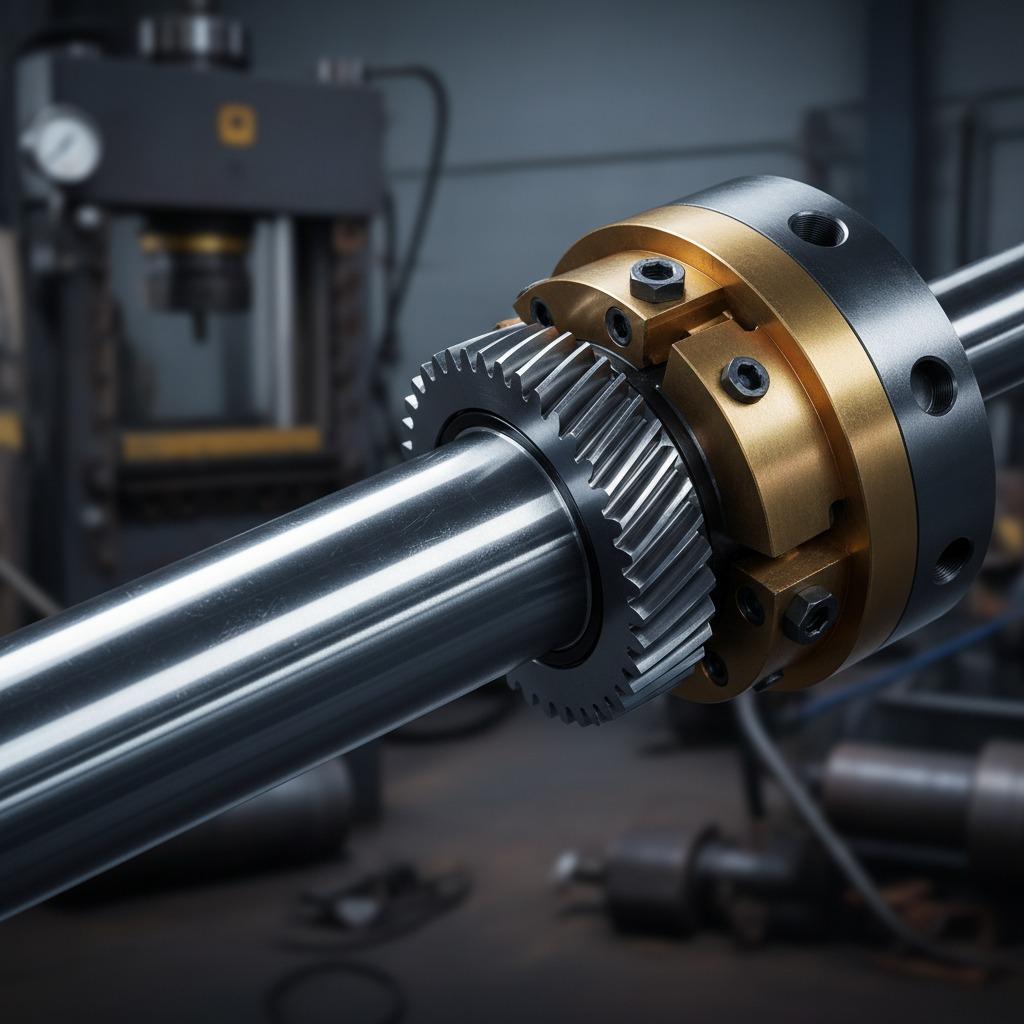

Inside Zhongteli’s Mechanical Jack Design

Zhongteli integrates forged steel construction with gear precision and ergonomic crank designs for long-lasting performance.

Product Highlights:

-

All-Forged Steel Structure – Supports heavy static and dynamic loads.

-

Precision Worm Gear System – Converts manual effort into efficient lift.

-

High-Torque Thread Shaft – Ensures smooth vertical movement under load.

-

Zinc or Epoxy Coating – Provides corrosion and abrasion protection.

-

Optional Side or Top Wind Handle – For flexible operation.

Every Zhongteli mechanical trailer jack undergoes torque, fatigue, and load endurance testing under ISO 9001 and EN 12195-3 standards.

Common Industrial and Field Applications

Zhongteli’s mechanical jacks are widely used across sectors that need durable, maintenance-free lifting equipment:

-

Construction Site Equipment Trailers – Reliable lifting under heavy loads.

-

Agricultural Implements – Simple operation in dusty or muddy fields.

-

Cargo and Freight Trailers – Smooth coupling and decoupling.

-

Utility Trailers – Steady lifting for small industrial fleets.

-

OEM Manufacturing Lines – Ideal for global export and brand customization.

As noted by the National Highway Traffic Safety Administration (NHTSA), mechanical lifting systems reduce risk by ensuring manual control even during system failure, especially in mobile towing environments.

Choosing the Right Mechanical Trailer Jack

| Application | Model Type | Capacity | Operation | Coating | Key Feature |

|---|---|---|---|---|---|

| Cargo Trailer | Top Wind | 3,000–5,000 lbs | Manual Gear | Zinc | Compact and easy to handle |

| Agricultural Trailer | Side Wind | 5,000–8,000 lbs | Screw Drive | Powder | High torque for uneven terrain |

| Construction Equipment | Drop Leg | 6,000–10,000 lbs | Dual Gear | Epoxy | Stability on soft ground |

| Industrial Fleet | Worm Gear | Up to 12,000 lbs | Hand Crank | Galvanized | Heavy-duty durability |

| OEM Orders | Custom Model | Variable | Configurable | Custom | Branding and private label |

Zhongteli engineers tailor mechanical jacks to customer needs — from compact screw mechanisms to dual-gear systems for higher torque efficiency.

Frequently Asked Questions

Q1: How does a mechanical jack lift without hydraulics?

It uses screw or worm gear systems to convert crank motion into vertical lift.

Q2: Are mechanical jacks suitable for outdoor or marine use?

Yes, Zhongteli offers galvanized or powder-coated finishes for all-weather protection.

Q3: What’s the lifespan of a mechanical trailer jack?

Typically over 8–10 years with proper use and minimal maintenance.

Q4: Can I request OEM designs or custom handles?

Yes — Zhongteli supports full OEM and private-label customization.

Enduring Power, Simple Mechanics

In environments where reliability matters more than automation, mechanical trailer jacks are the quiet workhorses of the industry.

With forged steel strength, smooth crank precision, and corrosion-resistant design, Zhongteli ensures lasting performance for every lift.

Explore more durable lifting solutions at Zhongteli’s homepage or contact us here to discuss OEM or export partnerships.