Industrial Trailer Jack Supplier: Engineered for Strength, Tested for Endurance

In the industrial world, where downtime means lost revenue, equipment reliability is non-negotiable.

A weak or inconsistent trailer jack can turn a simple loading task into a safety hazard. That’s why industrial-grade jacks are not just accessories — they’re critical components of operational stability.

Zhongteli, a trusted industrial trailer jack supplier, designs and manufactures forged, high-torque lifting systems that sustain performance under heavy loads, rugged terrain, and harsh environments.

The Real Challenge: Lifting Under Pressure

Industrial transport trailers operate under constant strain — uneven ground, variable loads, and long service cycles. Over time, even minor mechanical flaws can lead to catastrophic failure.

Common pain points include:

-

Bent shafts from overloading

-

Rust that seizes the crank mechanism

-

Thread wear causing sudden collapse

-

Unstable baseplates on soft terrain

According to SAE International mechanical standards, industrial lifting devices must maintain torque stability, thread precision, and anti-fatigue performance over 10,000 operational cycles. Zhongteli’s engineering process aligns precisely with those standards.

Industrial vs. Commercial Trailer Jacks

| Category | Industrial Trailer Jack | Commercial Trailer Jack |

|---|---|---|

| Load Range | 8,000–15,000 lbs | 2,000–5,000 lbs |

| Structure | Forged alloy steel | Mild steel tubing |

| Operation | Dual gear / screw system | Single gear manual |

| Durability | 10,000+ cycles | 3,000–5,000 cycles |

| Environment | Construction, logistics, mining | Light-duty hauling |

Industrial jacks are built for endurance — thick-walled tubes, sealed gears, and corrosion-proof coatings make them ideal for the most demanding lifting operations.

What Sets Zhongteli Apart as a Supplier

Zhongteli doesn’t just sell jacks — it engineers solutions.

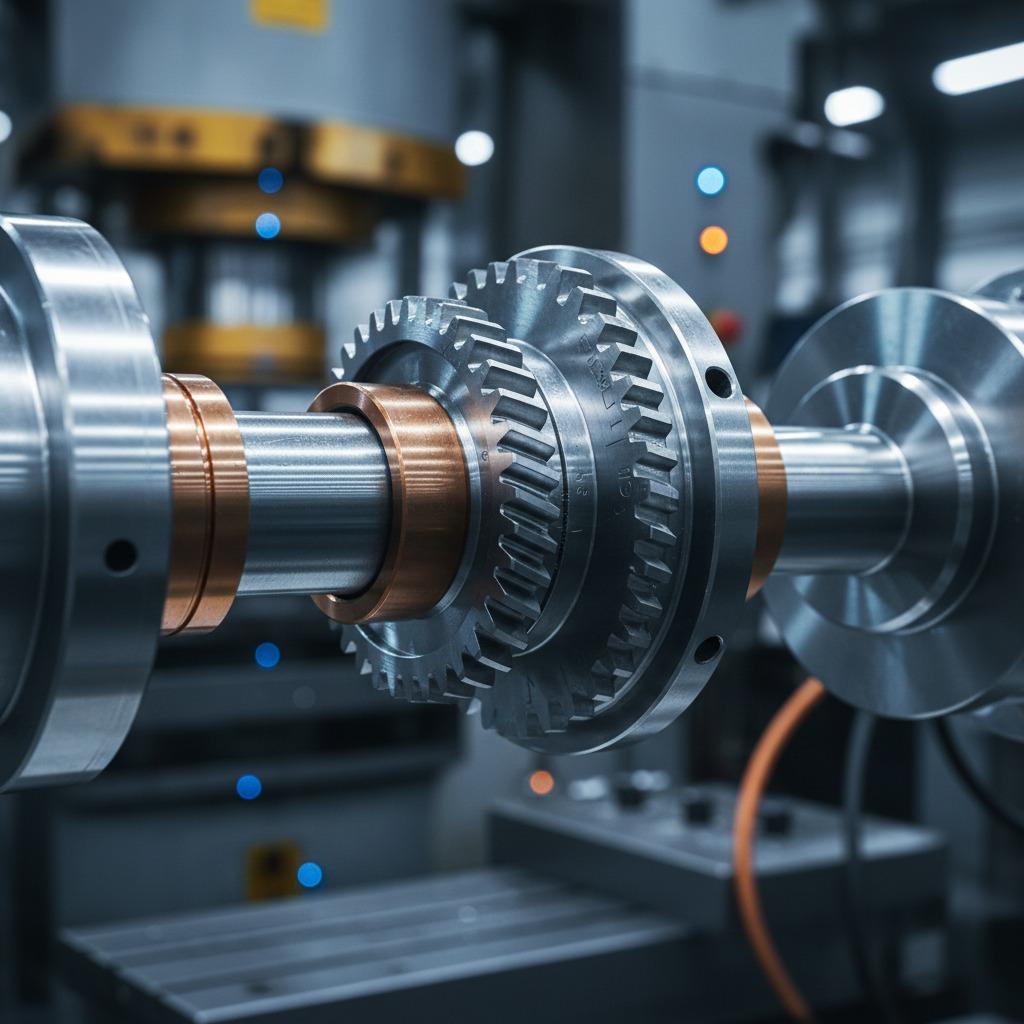

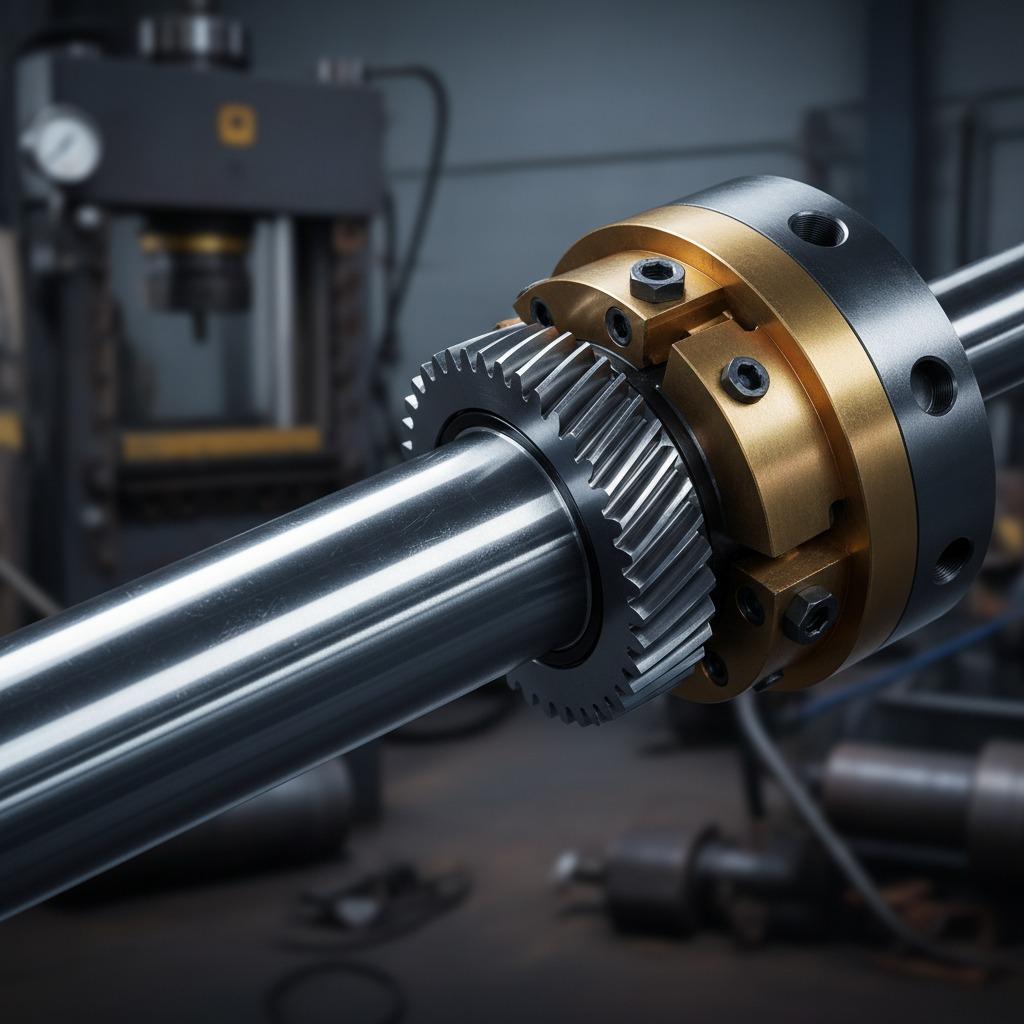

Each model is produced with forged precision, CNC-machined threads, and zinc or epoxy finishes for long-term corrosion defense.

Core advantages:

-

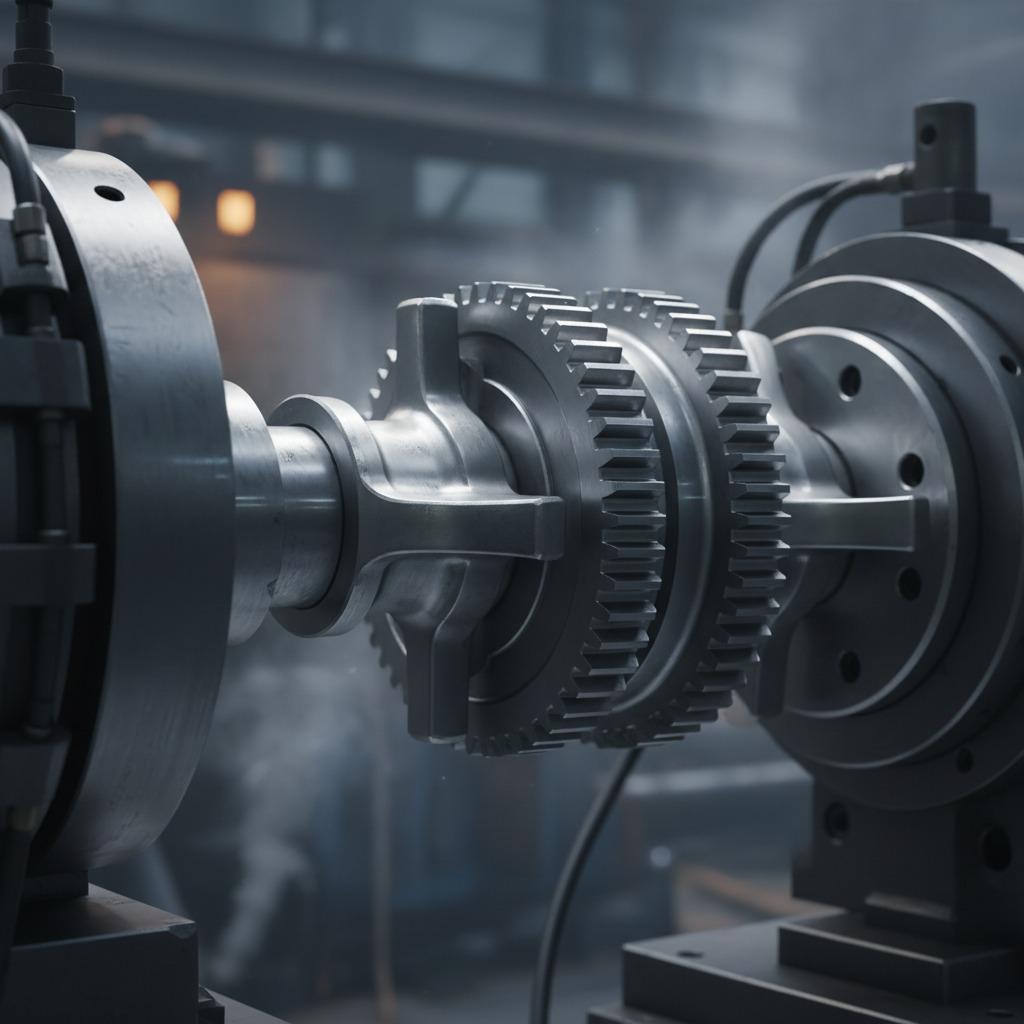

All-Forged Construction – No weld weakness or tube distortion.

-

High Torque Gear System – Smooth crank motion even under full load.

-

Corrosion-Resistant Coating – Zinc, epoxy, or hot-dip galvanized.

-

Custom Mounting Interfaces – OEM adaptable for diverse chassis designs.

-

Rigorous Load Testing – 100% torque and endurance inspection before shipment.

Every Zhongteli jack undergoes ISO 9001 and EN 12195-3 verification, ensuring consistent quality and export readiness.

Applications Across Industrial Fields

Zhongteli’s industrial trailer jacks are trusted by manufacturers and operators in sectors where reliability equals safety:

-

Construction & Mining Equipment – Handles vibration, mud, and heavy payloads.

-

Freight & Logistics Trailers – Reliable performance across long-distance hauls.

-

Agricultural Implements – Stable lifting in uneven terrain and wet conditions.

-

OEM Production Lines – Fully customized jacks for branded global equipment.

-

Energy & Utility Transporters – Rugged design for high-capacity machinery moves.

The National Highway Traffic Safety Administration (NHTSA) highlights that mechanical stability and corrosion resistance directly reduce the risk of coupling failures during field operations — the very foundation Zhongteli designs around.

Selecting the Right Industrial Trailer Jack

| Use Case | Type | Capacity | Coating | Key Feature |

|---|---|---|---|---|

| Heavy Cargo Transport | Dual Gear | 10,000 lbs | Zinc | High torque & low wear |

| Mining Equipment Trailer | Drop Leg | 12,000 lbs | HDG | Extreme corrosion resistance |

| Construction Machinery | Screw Drive | 15,000 lbs | Epoxy | Shock absorption & durability |

| Agricultural Trailer | Side Wind | 8,000 lbs | Powder | Compact with smooth control |

| OEM Export Model | Custom Design | Variable | Custom | Tailored to client specification |

Zhongteli’s R&D team collaborates directly with OEM partners to optimize each model’s structure, materials, and lift ratios — ensuring long service life with minimal maintenance.

Frequently Asked Questions

Q1: How does Zhongteli ensure product consistency across bulk orders?

Every batch is torque-tested and dimensionally verified through automated inspection systems.

Q2: Can industrial jacks be used outdoors year-round?

Yes — all models feature anti-rust finishes suitable for rain, dust, and coastal exposure.

Q3: What’s the typical service lifespan?

Over 10 years or 15,000 lift cycles, depending on environment and maintenance.

Q4: Does Zhongteli provide private-label manufacturing?

Yes, full OEM/ODM services with logo engraving, color coding, and packaging customization.

The Foundation of Industrial Reliability

For global OEMs and fleet operators, reliability isn’t optional — it’s engineered.

Zhongteli’s industrial trailer jacks combine strength, precision, and protection, ensuring seamless performance under pressure.

Experience engineered endurance — visit Zhongteli’s homepage or contact us here to explore OEM supply partnerships.