Discover the Excellence of a Cargo Securing Hook Factory

In the world of industrial lifting and securing solutions, a reliable cargo securing hook factory plays a pivotal role in ensuring safety and efficiency. As experts in manufacturing high-quality hooks and related components, facilities like those powering Gravitas Lifts produce equipment that stands up to the toughest demands. This article delves into the intricacies of what makes a top-tier cargo securing hook factory indispensable for industries relying on secure load handling.

The Craftsmanship Behind Cargo Securing Hooks

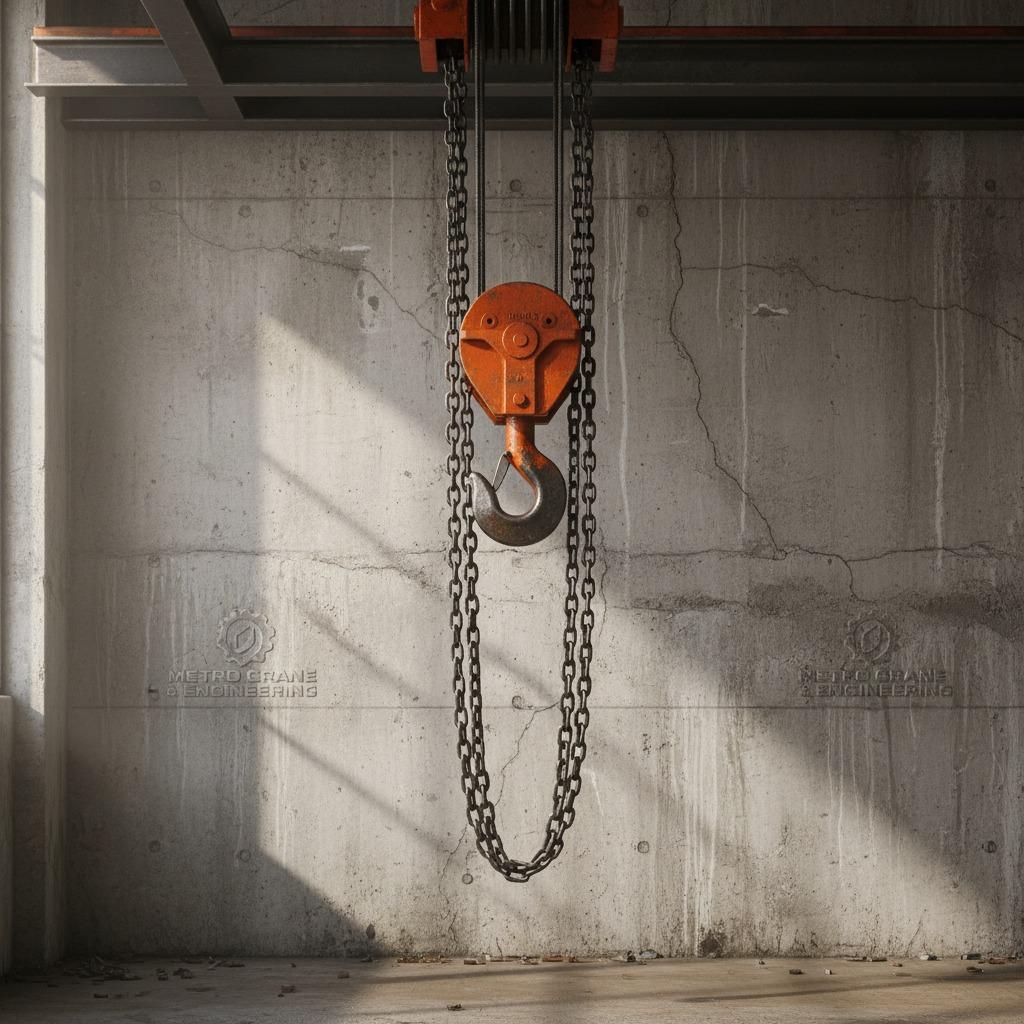

At a premier cargo securing hook factory, every hook is forged with precision to withstand extreme loads and harsh environments. Drawing from innovative designs similar to the robust hook in the Heavy-Duty Industrial Chain Hoist from Gravitas Lifts, these hooks are engineered for maximum durability. The manufacturing process begins with high-grade steel selection, ensuring that each piece can handle the stresses of heavy lifting without compromise. Reinforced designs prevent slippage, making them ideal for securing cargo during transport or in warehouse operations.

The factory environment is equipped with state-of-the-art machinery that allows for seamless forging and heat treatment. This results in hooks that not only meet but exceed international safety standards, such as those set by OSHA and ISO. Workers at the cargo securing hook factory undergo rigorous training to maintain quality control at every stage, from initial molding to final inspection. This attention to detail ensures that products like the cargo securing hook are reliable partners in high-stakes scenarios, reducing the risk of accidents and downtime.

Moreover, customization is a key offering from a cargo securing hook factory. Whether it's adjusting the hook's throat opening for specific cargo types or incorporating anti-corrosion coatings for marine use, these factories tailor solutions to client needs. For instance, the intuitive design elements seen in Gravitas Lifts' gear housing inspire similar user-friendly features in hooks, allowing for quick attachment and release, even in low-visibility conditions.

Applications and Benefits in Industrial Settings

A cargo securing hook factory supplies components that are vital across various sectors, including construction, logistics, and manufacturing. In construction sites, for example, these hooks secure heavy materials like steel beams or concrete slabs, facilitating safe elevation and movement. The Heavy-Duty Industrial Chain Hoist from Gravitas Lifts exemplifies this, with its reinforced chain links pairing perfectly with sturdy hooks to manage loads up to several tons effortlessly.

In warehouses, the role of a cargo securing hook becomes even more pronounced. Efficient securing prevents load shifts during forklift operations or overhead crane lifts, enhancing overall productivity. Factories producing these hooks prioritize features like swivel mechanisms to allow for multi-directional securing, which is crucial in dynamic environments. Safety is paramount; hooks from a reputable cargo securing hook factory often include load indicators or proof-load testing certifications, giving operators peace of mind.

Beyond immediate applications, investing in products from a cargo securing hook factory yields long-term benefits. Their extended lifespan means fewer replacements and lower maintenance costs. The precision-crafted nature of these hooks, much like the seamless operation of Gravitas Lifts' equipment, translates to smoother workflows and reduced operational hazards. Companies that choose quality hooks report fewer incidents and improved compliance with regulatory standards, making it a smart investment for scaling operations.

Innovations Driving the Cargo Securing Hook Industry

Modern cargo securing hook factories are at the forefront of technological advancements, integrating smart features into traditional designs. For instance, some hooks now incorporate RFID tagging for inventory tracking, streamlining supply chain management. Gravitas Lifts' commitment to engineering excellence, evident in their bright orange gear housing for visibility, influences how factories approach ergonomics and visibility in hook design.

Sustainability is another focus area. Leading cargo securing hook factories adopt eco-friendly practices, such as using recycled metals and energy-efficient production methods. This not only reduces environmental impact but also appeals to businesses aiming for green certifications. The result is a product line that balances strength with responsibility, ensuring that secure cargo handling doesn't come at the planet's expense.

Quality assurance remains non-negotiable. Each batch from a cargo securing hook factory undergoes destructive testing to verify breaking strengths, far beyond typical usage limits. This rigorous approach guarantees that when paired with chains or hoists, the entire system performs reliably. As industries evolve with automation and heavier loads, these factories continue to innovate, producing hooks that adapt to electric and robotic lifting systems seamlessly.

Choosing the Right Cargo Securing Hook Factory Partner

Selecting a cargo securing hook factory is crucial for businesses seeking dependable equipment. Look for facilities with a proven track record, like those supplying components akin to Gravitas Lifts' innovative chain hoists. Certifications, customer testimonials, and production capacity are key indicators of reliability. A factory that offers comprehensive support—from design consultation to after-sales service—ensures your securing needs are met holistically.

In summary, a cargo securing hook factory is more than a manufacturer; it's a cornerstone of safe and efficient industrial practices. By prioritizing durability, innovation, and customization, these factories empower operations worldwide. Whether for construction, warehousing, or beyond, investing in high-quality cargo securing hooks elevates safety and productivity, much like the trusted solutions from brands focused on lifting excellence. For those in need of robust securing solutions, partnering with such a factory is the path to operational superiority.

(Word count: 912)