Forged Hook with Safety Latch OEM: Engineered Excellence for Industrial Lifting

In the world of industrial lifting and rigging, the forged hook with safety latch OEM stands out as a critical component for ensuring safety and efficiency. As a leading provider of high-quality lifting solutions, Gravitas Lifts specializes in OEM manufacturing of these essential parts, delivering products that meet the rigorous demands of construction, manufacturing, and warehouse operations. This article explores the features, benefits, and applications of the forged hook with safety latch OEM, highlighting why it's a must-have for professionals seeking reliable performance.

Understanding the Forged Hook with Safety Latch OEM

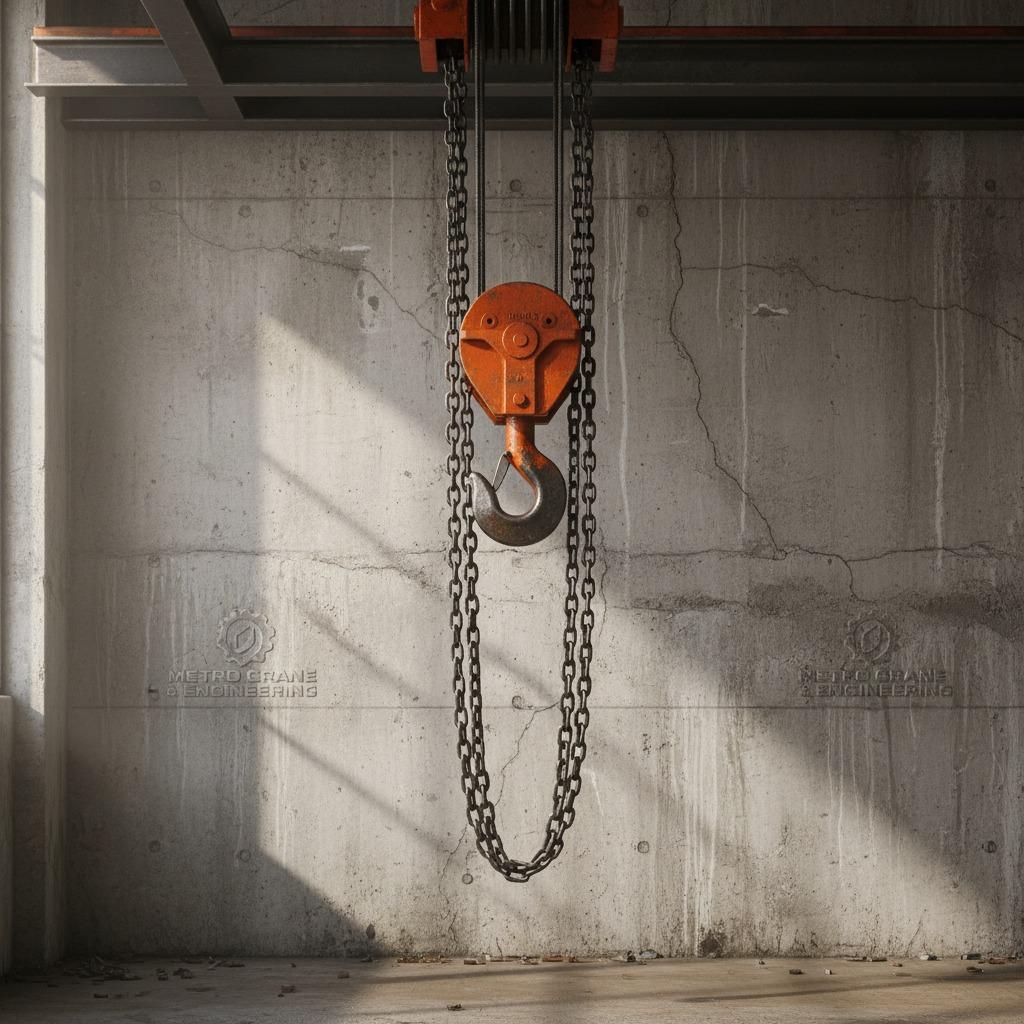

A forged hook with safety latch OEM is precision-engineered from high-strength steel to withstand extreme loads without compromising integrity. The forging process enhances the hook's durability, making it resistant to deformation and fatigue that can occur in harsh environments. The integrated safety latch prevents accidental disengagement of loads, adding an extra layer of protection during lifting tasks. As an OEM product from Gravitas Lifts, these hooks are customizable to fit specific client specifications, ensuring seamless integration into existing hoist and rigging systems.

The design of the forged hook with safety latch OEM emphasizes both functionality and user safety. Its robust construction allows for a maximum load capacity that aligns with industry standards, while the latch mechanism operates smoothly to secure slings, chains, or other attachments. This OEM approach means businesses can source hooks tailored to their needs, whether for heavy-duty chain hoists or overhead cranes, reducing downtime and enhancing overall operational reliability.

Key Features and Advantages

One of the standout features of the forged hook with safety latch OEM is its corrosion-resistant finish, which protects against environmental factors like moisture and chemicals commonly found in industrial settings. Gravitas Lifts ensures that each hook undergoes rigorous testing to guarantee compliance with safety regulations, providing peace of mind to operators. The ergonomic design of the latch allows for quick and easy engagement, speeding up loading and unloading processes without sacrificing security.

In addition to durability, the forged hook with safety latch OEM offers superior load distribution, minimizing stress points that could lead to failures. This is particularly beneficial when paired with the Gravitas Lifts Industrial Chain Hoist, which features a heavy-duty hook designed for maximum bearing capacity. The combination results in a lifting system that's not only powerful but also incredibly safe, reducing the risk of accidents in high-stakes environments like manufacturing plants or construction sites.

Customization options in the OEM process allow for variations in hook size, load ratings, and even color coding for easy identification—such as the eye-catching orange housing seen in Gravitas Lifts products. This versatility makes the forged hook with safety latch OEM ideal for a wide range of applications, from light assembly line work to heavy material handling in warehouses.

Applications in Industrial Settings

The forged hook with safety latch OEM finds its place in numerous industrial applications where lifting heavy loads is routine. In construction, it's used to hoist steel beams and concrete forms securely, ensuring precise placement without slippage. For manufacturing facilities, these hooks facilitate the movement of machinery parts and assemblies, supporting efficient production lines. Warehouses benefit from their reliability in stacking pallets and inventory, optimizing space and workflow.

When integrated with advanced chain hoists like those from Gravitas Lifts, the forged hook with safety latch OEM enhances overall system performance. The precision-engineered chains work in tandem with the hook to provide smooth operation, minimizing friction and extending the lifespan of the equipment. This synergy is crucial in environments where consistent heavy use is the norm, allowing businesses to maintain productivity without frequent replacements or repairs.

Moreover, the safety features of the forged hook with safety latch OEM make it indispensable for compliance with occupational health standards. By preventing load drops, it protects workers and assets, potentially lowering insurance costs and liability risks for companies. Gravitas Lifts' commitment to engineered reliability ensures that these OEM hooks perform flawlessly in demanding conditions, redefining excellence in industrial lifting solutions.

Why Choose Gravitas Lifts for Your OEM Needs

Gravitas Lifts stands as a pinnacle of innovation in the lifting industry, offering the forged hook with safety latch OEM as part of a comprehensive lineup of products designed for toughness and visibility. The company's robust steel structures and advanced mechanical mechanisms deliver unmatched efficiency, making their hoists and components a preferred choice for professionals worldwide. With a focus on simple yet sturdy designs, installation and operation become straightforward, empowering teams to focus on their core tasks.

Opting for OEM forged hooks from Gravitas Lifts means investing in longevity and performance. Their products, including the Industrial Chain Hoist, are built to endure consistent heavy use, ensuring that your operations run smoothly year after year. The heavy-duty hook's engineering for maximum load-bearing capacity, combined with the safety latch, provides secure lifting that's essential for any industrial application.

Furthermore, Gravitas Lifts prioritizes customer satisfaction through personalized OEM services, allowing for tailored solutions that align with specific project requirements. Whether you're upgrading existing equipment or outfitting a new facility, their expertise in forged hook with safety latch OEM production guarantees results that exceed expectations. This dedication to quality and reliability positions Gravitas Lifts as a trusted partner in redefining industrial lifting excellence.

Maintenance and Best Practices

To maximize the benefits of the forged hook with safety latch OEM, regular maintenance is key. Inspect the hook and latch for signs of wear, such as cracks or bending, before each use. Lubricate moving parts to ensure smooth operation, and store the equipment in a dry environment to prevent corrosion. Following these practices extends the service life of your Gravitas Lifts components, maintaining their peak performance.

Training operators on proper usage of the forged hook with safety latch OEM is equally important. Emphasize the importance of never exceeding load limits and always engaging the safety latch fully. By incorporating these best practices, businesses can leverage the full potential of their lifting systems, enhancing safety and efficiency across all operations.

In summary, the forged hook with safety latch OEM from Gravitas Lifts represents the forefront of industrial lifting technology. Its durable construction, safety features, and customizable OEM options make it an invaluable asset for any heavy-duty application. Choose Gravitas Lifts for solutions engineered for reliability, and elevate your lifting capabilities to new heights of excellence.