Choosing the Right High Tensile Lifting Hook Supplier for Your Industrial Needs

When it comes to heavy-duty lifting operations in industrial environments, selecting a reliable high tensile lifting hook supplier is crucial for ensuring safety, efficiency, and longevity of your equipment. High tensile lifting hooks are engineered to withstand extreme loads and harsh conditions, making them indispensable in sectors like construction, manufacturing, and warehousing. As industries push the boundaries of what’s possible with heavier payloads and more demanding applications, partnering with a trusted high tensile lifting hook supplier can make all the difference in maintaining operational excellence.

The Importance of High Tensile Strength in Lifting Hooks

High tensile lifting hooks are designed with superior material properties that allow them to endure significant stress without deforming or failing. Typically forged from high-grade alloy steel, these hooks offer tensile strengths far exceeding standard lifting hardware, often rated for loads up to several tons. This strength is vital in preventing accidents and downtime, as a subpar hook could snap under pressure, leading to catastrophic consequences. When sourcing from a reputable high tensile lifting hook supplier, you gain access to products that comply with international standards like ASME B30.10 and EN 1677, ensuring they meet rigorous safety protocols. Moreover, these suppliers often provide detailed load charts and testing certifications, giving you peace of mind during inspections and audits.

The engineering behind high tensile lifting hooks involves advanced heat treatment processes that enhance hardness and toughness. For instance, hooks with a tensile strength of over 1000 MPa can handle dynamic loads in dynamic environments, such as overhead cranes or hoists. A good high tensile lifting hook supplier will also emphasize ergonomic designs, like safety latches and swivel features, to prevent accidental disengagement and facilitate smooth rigging. By investing in such quality, businesses not only safeguard their workforce but also optimize workflow, reducing the need for frequent replacements and maintenance.

Key Features to Look for in a High Tensile Lifting Hook Supplier

Reliability is the cornerstone of any high tensile lifting hook supplier worth their salt. Look for suppliers who specialize in custom fabrication, allowing you to tailor hooks to specific load requirements, whether it's a clevis or ramshorn design. Top-tier suppliers invest in state-of-the-art manufacturing facilities equipped with CNC machining and non-destructive testing methods to ensure each hook meets or exceeds performance benchmarks. Additionally, a forward-thinking high tensile lifting hook supplier will offer comprehensive support, including on-site training for proper usage and integration with complementary lifting gear like chain slings or wire ropes.

Beyond the product itself, evaluate the supplier's commitment to sustainability and innovation. Many leading high tensile lifting hook suppliers now incorporate eco-friendly practices, such as using recyclable materials and energy-efficient production lines, which align with modern corporate responsibility goals. Customer service is another pivotal aspect; a supplier that provides quick turnaround times, competitive pricing, and global shipping options can streamline your procurement process. For example, suppliers with ISO 9001 certification demonstrate a dedication to quality management, minimizing defects and enhancing overall value.

Integrating High Tensile Lifting Hooks with Chain Blocks for Optimal Performance

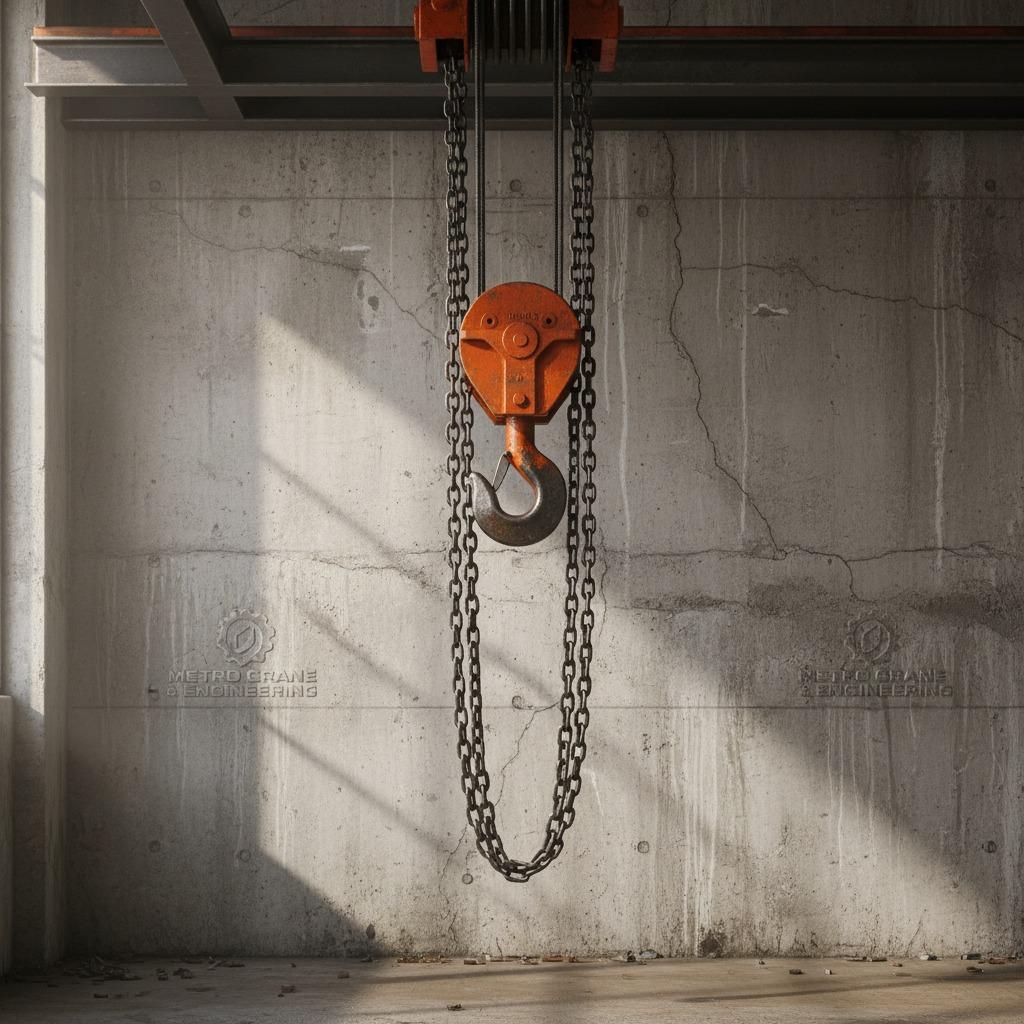

To maximize the benefits of high tensile lifting hooks, pairing them with robust chain blocks is a strategic move. Consider the Gravitas Lifts Chain Block, a pinnacle of engineering excellence built to handle the toughest lifting tasks with unmatched reliability. This robust chain block features a heavy-duty hook, designed for maximum load-bearing capacity, complemented by durable steel chains ensuring smooth operation under pressure. The orange housing encases a precision-engineered mechanism that guarantees safety and efficiency in every lift. Sourcing from a high tensile lifting hook supplier that complements such products ensures seamless compatibility and enhanced system performance.

With a focus on durability, the Gravitas Lifts Chain Block is assembled to withstand harsh environments, offering longevity and consistent performance. Perfect for industrial settings, this chain block ensures your lifting needs are met with precision and reliability. When selecting a high tensile lifting hook supplier, inquire about bundles or kits that include chain blocks, as this can simplify assembly and reduce costs. The integration of high tensile lifting hooks with these devices allows for precise control in vertical lifts, minimizing sway and improving accuracy in positioning heavy loads. Regular maintenance tips from your supplier, such as lubrication schedules and inspection protocols, further extend the lifespan of these components.

Benefits of Partnering with a Trusted High Tensile Lifting Hook Supplier

Partnering with an established high tensile lifting hook supplier yields numerous advantages, from cost savings to enhanced operational safety. Reliable suppliers often provide bulk discounts and volume-based pricing, making it economical for large-scale projects. Moreover, they stay ahead of industry trends, offering hooks with advanced features like anti-corrosion coatings for marine or chemical environments. This proactive approach helps businesses adapt to evolving regulations and technological advancements without overhauling their equipment.

Safety is paramount, and a quality high tensile lifting hook supplier prioritizes it through rigorous quality assurance. Their products undergo drop tests, fatigue simulations, and overload assessments to simulate real-world scenarios. This diligence translates to fewer workplace incidents and lower insurance premiums for your operations. Additionally, many suppliers offer warranty programs covering manufacturing defects, providing financial protection and confidence in your investment. By choosing a supplier with a proven track record, you foster long-term relationships that can lead to customized solutions tailored to your unique challenges.

Future Trends in High Tensile Lifting Hook Technology

The landscape of high tensile lifting hooks is evolving rapidly, with innovations driven by smart technology and material science. Forward-looking high tensile lifting hook suppliers are incorporating IoT sensors into hooks for real-time load monitoring, alerting operators to potential overloads via mobile apps. Lightweight composites and nanotechnology coatings are also emerging, reducing weight without compromising strength, which is ideal for mobile lifting applications. As automation increases in industries, suppliers are developing hooks compatible with robotic systems, ensuring seamless integration in smart factories.

Sustainability remains a key driver, with suppliers exploring bio-based alloys and recyclable designs to minimize environmental impact. Regulatory bodies are pushing for greener practices, and a committed high tensile lifting hook supplier will align with these standards. Looking ahead, expect enhanced traceability through blockchain for supply chain transparency, allowing buyers to verify the origin and testing history of each hook. By staying informed through your supplier's updates and webinars, you can future-proof your lifting operations.

Conclusion: Elevate Your Lifting Operations Today

In summary, selecting the right high tensile lifting hook supplier is essential for any operation reliant on heavy lifting. From superior strength and safety features to innovative integrations like the Gravitas Lifts Chain Block, these partnerships empower businesses to achieve more with less risk. Whether you're upgrading existing equipment or outfitting a new facility, prioritize suppliers that deliver quality, support, and value. Experience engineered dependability and take your industrial efficiency to new heights with the best high tensile lifting hook options available.