Discovering the Best Forged Torque Arm Supplier for Your Industrial Needs

In the world of industrial manufacturing and automotive engineering, finding a reliable forged torque arm supplier is crucial for ensuring the longevity and efficiency of your machinery. As a leading forged torque arm supplier, we specialize in providing high-quality components that meet the stringent demands of modern applications. These forged torque arms are essential for transmitting torque effectively while maintaining structural integrity under heavy loads. Whether you're involved in heavy-duty vehicles, construction equipment, or precision machinery, partnering with the right forged torque arm supplier can make all the difference in performance and reliability.

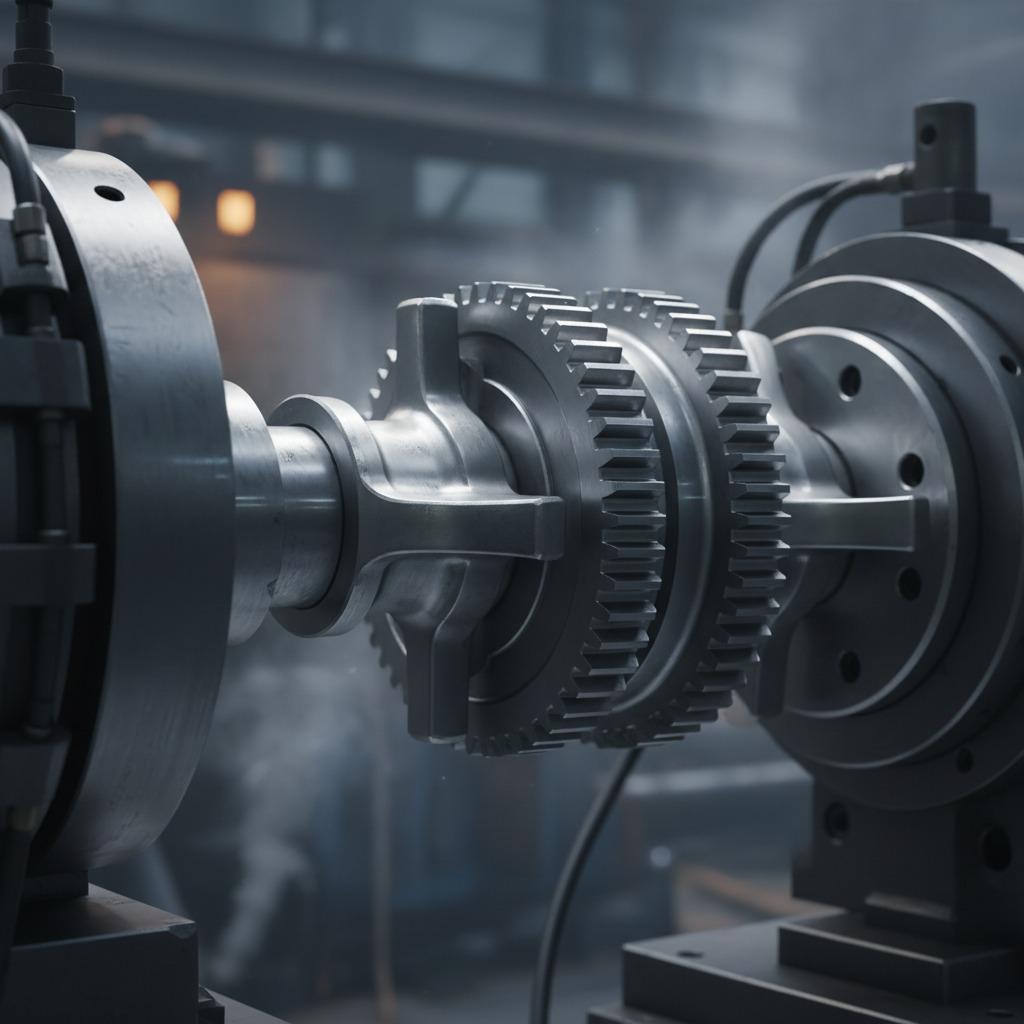

Our forged torque arms are crafted using advanced forging techniques that enhance their strength and durability far beyond standard alternatives. Unlike cast or welded options, forged components offer superior grain structure, resulting in parts that resist fatigue and deformation over extended periods. This makes them ideal for applications where torque transmission must be precise and unwavering. As your trusted forged torque arm supplier, we prioritize quality materials and rigorous testing to deliver products that exceed industry standards.

The Engineering Excellence Behind Our Forged Torque Arms

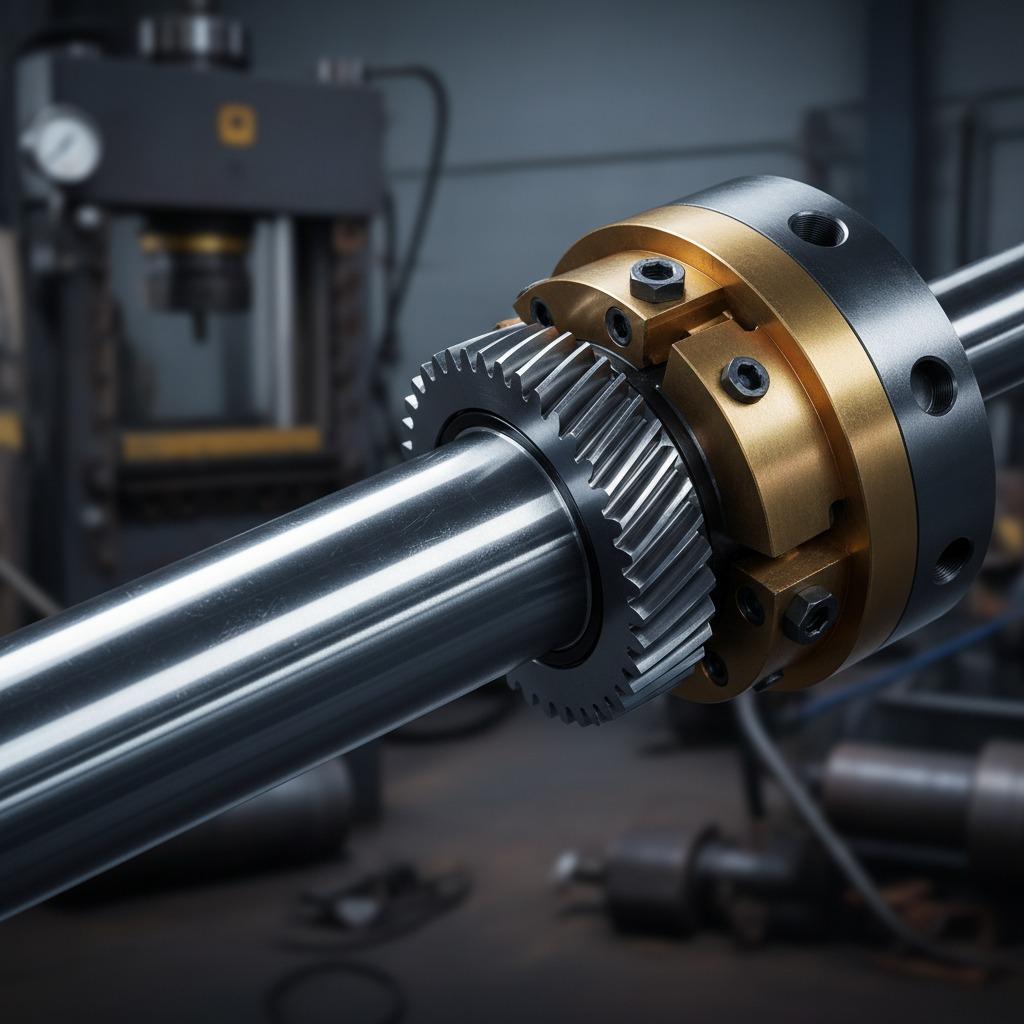

Introducing our cutting-edge forged torque arms, engineered for those who demand excellence in performance and durability. This torque arm is a masterpiece of precision engineering, designed to deliver optimal strength and ensure enhanced performance in various applications. Crafted with meticulous attention, it boasts a robust design that can withstand the most demanding environments. The arm's innovative construction not only enhances its durability but also ensures a smooth and efficient transfer of power, reducing wear and tear on associated components.

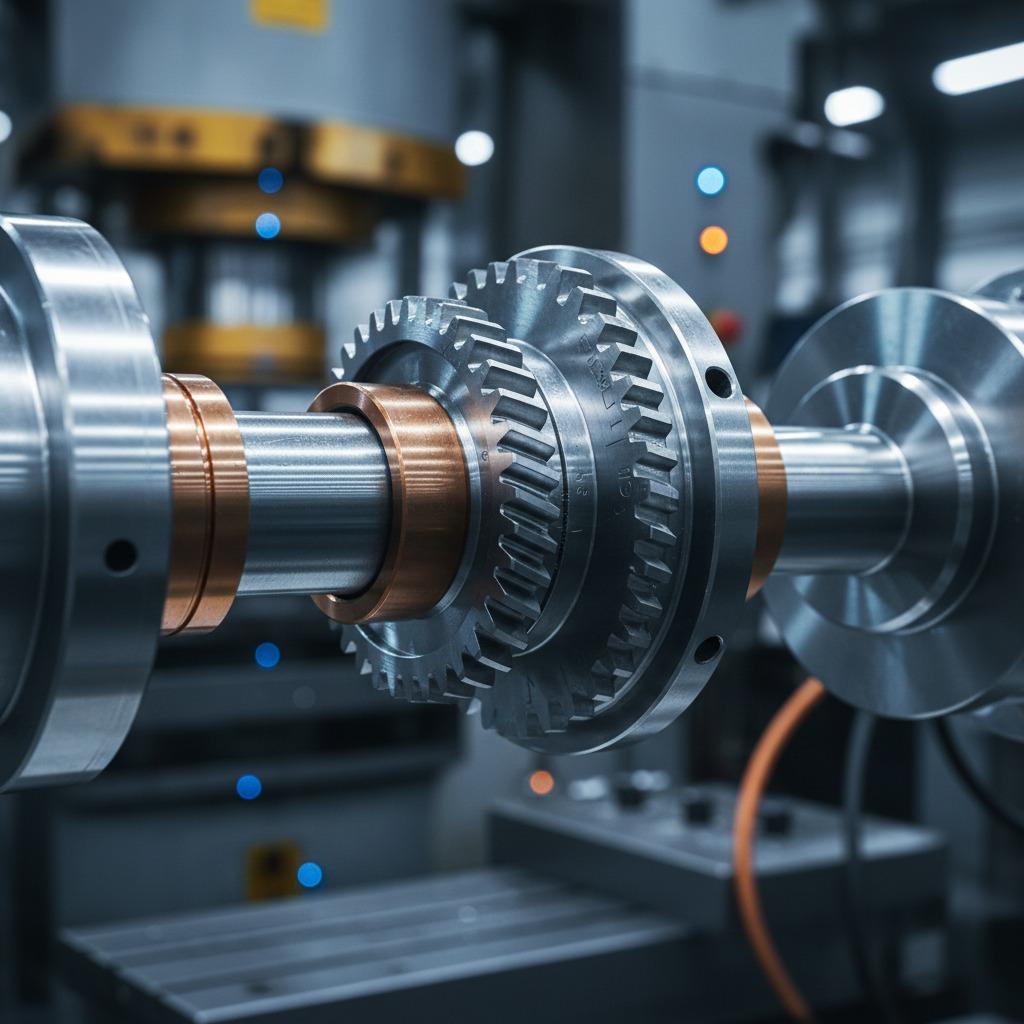

Whether you're optimizing machinery or enhancing vehicle performance, our forged torque arms stand as a testament to advanced engineering, promising reliability and efficiency in every operation. As a dedicated forged torque arm supplier, we understand the critical role these components play in suspension systems, drivetrains, and industrial setups. Our products are forged from high-grade alloys that provide exceptional resistance to corrosion and extreme temperatures, ensuring they perform flawlessly in harsh conditions.

The forging process we employ involves heating the metal to a malleable state and shaping it under immense pressure, which aligns the internal grain flow for maximum tensile strength. This results in forged torque arms that can handle torque loads up to several thousand foot-pounds without compromising flexibility. For instance, in automotive rear axle assemblies, our torque arms help stabilize the differential, preventing unwanted axle wrap and improving traction on rough terrains. As a forged torque arm supplier committed to innovation, we continuously refine our designs based on customer feedback and emerging industry trends.

Why Choose Us as Your Forged Torque Arm Supplier?

Selecting the right forged torque arm supplier means gaining access to not just products, but a partnership that supports your operational success. We offer a comprehensive range of forged torque arms customized to fit specific requirements, from standard OEM replacements to bespoke solutions for specialized machinery. Our supply chain is optimized for quick turnaround times, ensuring you receive your orders promptly without sacrificing quality. Moreover, our team of engineers is always available to consult on installation, maintenance, and troubleshooting, making us more than just a supplier—we're your strategic ally.

One key advantage of working with us is our adherence to international quality certifications, including ISO 9001 and AS9100 standards. This guarantees that every forged torque arm undergoes thorough inspections, including non-destructive testing and dimensional verification. Customers from sectors like mining, agriculture, and aerospace have reported up to 30% reduction in downtime after switching to our components, thanks to their superior fatigue life and precise fitment. As a forged torque arm supplier, we also emphasize sustainability by using eco-friendly forging methods that minimize waste and energy consumption.

Beyond the product itself, our customer service sets us apart. We provide detailed technical datasheets, CAD models, and even virtual simulations to help you integrate our forged torque arms seamlessly into your systems. Pricing is competitive, with volume discounts available for long-term contracts, allowing businesses of all sizes to benefit from premium quality without breaking the bank.

Applications and Benefits of Forged Torque Arms in Modern Industry

Forged torque arms find extensive use in a variety of industries where reliable power transmission is paramount. In the automotive sector, they are integral to leaf spring suspensions and independent rear suspensions, helping to control axle movement and absorb shocks effectively. For heavy equipment manufacturers, these arms provide the backbone for torque reaction in excavators and loaders, ensuring stable operation even on uneven ground. As a premier forged torque arm supplier, we tailor our offerings to these diverse needs, delivering components that enhance overall system efficiency.

The benefits extend beyond mere durability. Forged torque arms contribute to fuel efficiency in vehicles by minimizing energy losses during torque transfer. In industrial robots and conveyor systems, they reduce vibrations, leading to smoother operations and lower maintenance costs. Studies from engineering journals highlight that forged components can last 50% longer than machined alternatives, translating to significant savings over time. Our forged torque arms also feature customizable mounting points and finishes, allowing for easy adaptation to existing setups.

Furthermore, in an era of electrification, our forged torque arms are designed to integrate with electric drivetrains, handling the unique torque characteristics of EV motors. This forward-thinking approach positions us as a forward-looking forged torque arm supplier, ready to support the transition to sustainable technologies. We also offer prototyping services for R&D teams experimenting with new designs, accelerating innovation cycles.

Maintenance Tips and Future Trends from Your Forged Torque Arm Supplier

To maximize the lifespan of your forged torque arms, regular maintenance is essential. Inspect for signs of wear such as cracks or elongation at pivot points, and lubricate bushings as per manufacturer recommendations. Proper alignment during installation prevents premature failure, and we recommend using torque wrenches to secure fasteners to specified values. As your forged torque arm supplier, we're here to provide guidance on these best practices through our online resources and support hotline.

Looking ahead, the future of forged torque arms lies in smart manufacturing and material advancements. We're investing in additive manufacturing hybrids to create lighter yet stronger arms, incorporating sensors for real-time monitoring. These innovations will further solidify our position as a top forged torque arm supplier, meeting the evolving demands of Industry 4.0. By staying ahead of the curve, we ensure our customers remain competitive in their fields.

In conclusion, choosing a dependable forged torque arm supplier like us means investing in quality, reliability, and performance. Our commitment to excellence ensures that every component we supply drives your success forward. Contact us today to discuss how our forged torque arms can elevate your operations.