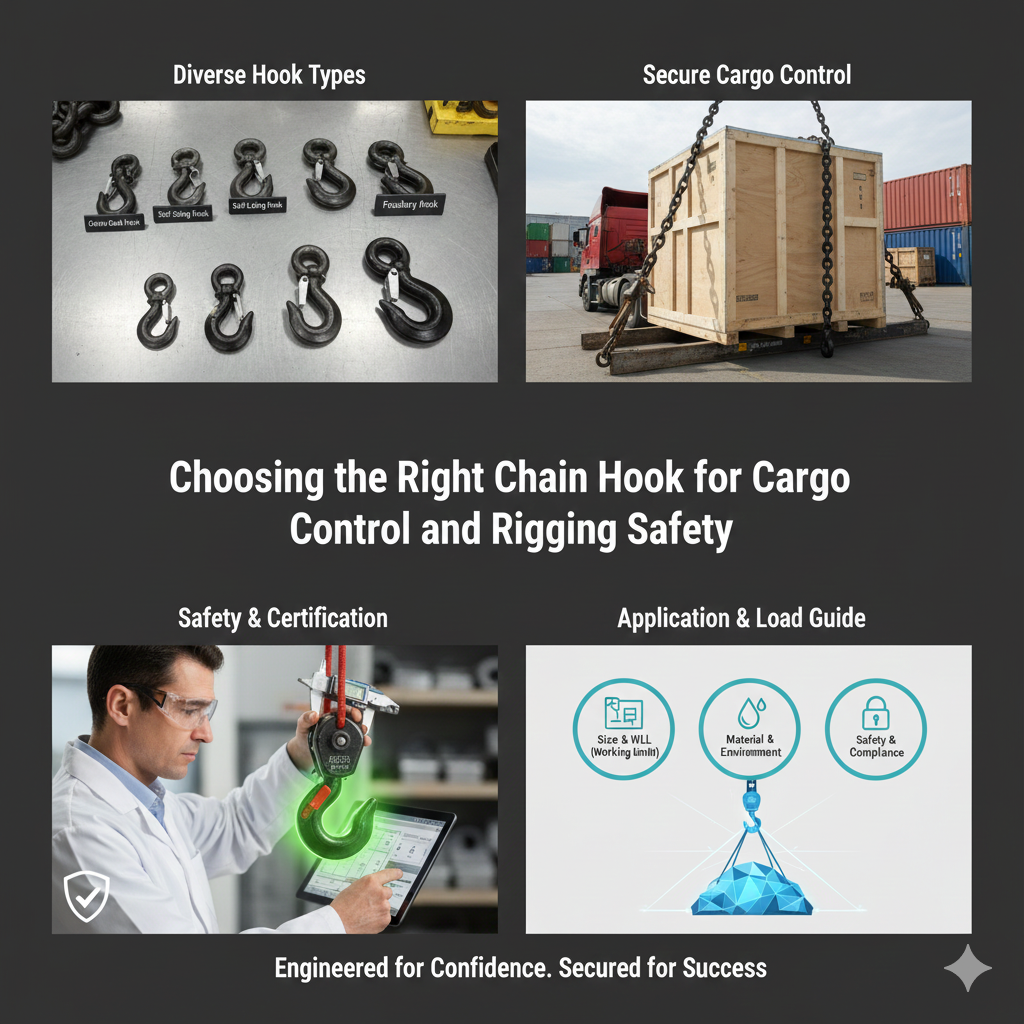

Choosing the Right Chain Hook for Cargo Control and Rigging Safety

Whether in construction yards, transport fleets, or offshore operations, chain hooks serve as the crucial link that keeps loads secure and operations safe.

For a chain hook supplier, every detail — from steel composition to surface finish — determines whether a product withstands years of heavy lifting or fails prematurely.

That’s why global buyers and OEM partners turn to Zhongteli, a professional supplier of forged chain hooks engineered for strength, durability, and compliance with the world’s most rigorous standards.

Why Quality Chain Hooks Define Operational Safety

In high-load environments, hooks endure dynamic tension, vibration, and environmental corrosion. Substandard cast hooks or non-certified imports often lack the mechanical strength and fatigue resistance required for daily operations.

Buyer Pain Points Include:

-

Hooks bending or cracking under load peaks.

-

Dimensional inconsistencies causing chain slippage.

-

Rust or coating failure after short-term outdoor exposure.

-

Missing certificates for ISO or ASME compliance.

According to OSHA and ASME B30.10, every hook used in lifting and cargo restraint must maintain traceability and proof-test certification — otherwise, safety risks and insurance liabilities arise.

The Forging Principle Behind a Reliable Chain Hook

Zhongteli’s manufacturing process starts from premium 35CrMo or 42Cr alloy steel, selected for its high tensile strength and elongation capacity. Through closed-die hot forging, steel fibers follow the hook’s curve, reinforcing critical stress points.

Key Manufacturing Steps:

-

Billet Cutting & Heating — Temperature controlled at 1150–1250°C for uniform deformation.

-

Closed-Die Forging — Ensures grain flow alignment and eliminates air pockets.

-

CNC Machining — Guarantees precise pinhole and latch dimensions.

-

Heat Treatment — Quenching and tempering to reach 33–38 HRC hardness.

-

Surface Coating — Zinc plating, epoxy, or hot-dip galvanizing for corrosion resistance.

-

Proof Load Testing — Conducted at 2.5× the working load limit (WLL).

Every batch is serialized, tested, and verified under ISO 7597:2013 and EN 1677 for lifting compliance.

Forged vs. Cast Chain Hooks

| Feature | Forged Chain Hook | Cast Chain Hook |

|---|---|---|

| Structure | Directional grain flow | Random grain orientation |

| Load Capacity | 850–950 MPa tensile strength | 400–550 MPa |

| Fatigue Life | 10,000+ cycles | 3,000–4,000 cycles |

| Impact Resistance | Excellent | Poor at low temperatures |

| Safety Compliance | ISO, ASME, EN certified | Often uncertified |

Research by SAE International confirms that forged steel components maintain 30–50% higher fatigue strength than cast equivalents — critical for hooks exposed to vibration and repeated load cycling.

Zhongteli’s Competitive Edge as a Chain Hook Supplier

Zhongteli integrates forging, machining, and inspection under one system, ensuring product consistency and export readiness.

Supplier Advantages:

-

ISO 9001 & CE Certified Production

-

Material Traceability: Mill certificates with chemical composition records

-

OEM/ODM Customization: Hook geometry, branding, and surface finish options

-

Global Export Service: Packaging compliant with WTO trade and logistics regulations

-

Automated QC Line: Magnetic particle and ultrasonic testing before shipment

These systems make Zhongteli a long-term supplier to OEMs and distributors in North America, Europe, and the Middle East.

Applications Across Industries

Zhongteli’s chain hooks are engineered for demanding use cases across multiple industries:

-

Construction: Crane lifting, concrete handling, formwork rigging.

-

Marine: Salt-resistant hooks for deck and offshore lifting.

-

Logistics: Cargo securing and chain tension systems.

-

Mining: High-strength hooks for repetitive material movement.

-

OEM Integration: Embedded in customized rigging systems.

Each hook type is designed to match load geometry, working angle, and corrosion environment, ensuring safe performance in diverse industrial conditions.

Selecting the Right Chain Hook

| Application | Hook Type | Material | Coating | Capacity |

|---|---|---|---|---|

| Cargo Restraint | Clevis Hook | 35CrMo | Zinc | 5–10 T |

| Marine Lifting | Eye Hook | 42CrMo | HDG | 3–8 T |

| Construction Rigging | Grab Hook | Alloy Steel | Painted | 10–15 T |

| OEM Equipment | Custom Hook | Custom Alloy | OEM Finish | Up to 25 T |

When selecting hooks, consider load type, environment, and operating frequency. Zhongteli’s engineers provide mechanical analysis and corrosion-resistance recommendations for OEM buyers.

FAQ

Q1: What certifications do Zhongteli chain hooks meet?

All hooks comply with ISO 7597, EN 1677, and ASME B30.10.

Q2: Can hooks be customized for OEM supply?

Yes — custom geometry, branding, packaging, and coatings are available for export.

Q3: How are chain hooks tested before shipment?

Each batch undergoes proof load testing, hardness verification, and NDT inspection.

Q4: What’s the typical delivery lead time?

25–30 days depending on customization and order volume.

Forged Strength, Delivered Globally

A forged hook is more than a lifting component — it’s a safety commitment built into every link of your rigging system.

As a leading chain hook supplier, Zhongteli delivers globally certified products forged to perform in the world’s toughest environments.

For OEM partnerships or global distribution inquiries, explore Zhongteli’s homepage or contact us directly here.